If you’re debating between using glass or Plexiglass for a project, you may be wondering what the pros and cons of each are. A common misconception is that plexiglass is cheaper than glass – but this is not true. Here’s a breakdown of the differences between the two materials.

Plexiglass is lighter in weight and stronger than glass but it is more expensive and more easily scratched. It is clearer than glass but will yellow when exposed to UV light. Unlike glass, it can be easily machined: drilled, sawed, bent, and molded to form useful objects.

What is plexiglass?

Plexiglas® is the trade name for a type of acrylic sheet, made by the German company Roehm, from Poly(methyl methacrylate), or PMMA. It is now known by the generic name “Plexiglass“. Other brand names for the same product include Perspex®, Lucite®, and Acrylite®. For the purpose of this post, PMMA sheets will be referred to using the commonest US term: plexiglass.

Glass is a unique substance made by melting silica sand with various additives to make a vast range of clear or colored, transparent, or opaque products. Learn about annealed and tempered glass in this post.

Many products like windows, shelves, tabletops, and screens can be made with both plexiglass and glass. Read on to learn about the most important differences between the two materials.

As an Amazon Associate, I earn from qualifying purchases

Differences between plexiglass & glass

Plexiglass and glass are both transparent, non-crystalline, man-made materials with very wide commercial, domestic and industrial uses in modern life.

Both glass types are available with modifications (mainly surface coatings) designed to improve their performance. These include UV coatings for plexiglass, anti-glare coatings for picture framing, stain-resisting coatings for shower doors, low-E coatings for insulated glass, and coatings for plexiglass to improve hardness (eg LUXACRYL®), and many more.

in order to make an apples-to-apples comparison, we compare regular plexiglass with regular tempered glass in this post – but always remember that many upgrades are available.

The most important differences are summarized below:

Plexiglass is lighter than glass but more expensive

Plexiglass sheets are lighter in weight than glass making shipping less expensive and making handling and installation easier, especially for homeowners and non-professionals.

Contrary to popular misconception, however, plexiglass is more expensive than glass. Jump to these handy #price calculators to compare the weights and approximate retail pricing of plexiglass and tempered glass.

Plexiglass is easier to saw and drill than glass

Although some care and skill is needed to avoid chipping and cracking, plexiglass sheets can be cut by the home handyman using a table saw or circular saw with a fine-toothed blade. To protect the easily scratched surface, leave the protective paper on when sawing and drilling.

Plexiglass is easier to bend than glass

Using a hairdryer or, better still, a heat gun (like this one available from Amazon), the handy homeowner can bend plexiglass to fabricate custom shapes at home. Bending glass is not a home project: it requires temperatures in excess of 1100 degrees F and can only be done in factories (or workshops with kilns).

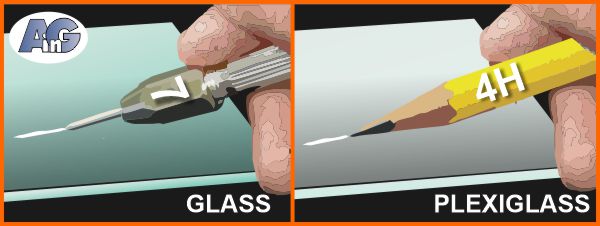

Thin plexiglass can be cut by scoring

Thin (1/8″ to 1/4″) plexiglass sheets cut be cut by scoring with a special tool (available here from Amazon). After scoring, the plexiglass can then be broken apart by bending, as shown in the image above.

Use patience to make multiple scores, on both sides of the sheet, in order to remove enough material to create the break.

In contrast, glass cannot be cut once it has been tempered and even annealed glass is tricky to cut and drill without skill and special tools.

Plexiglass is clearer than glass – but may yellow in the sun

The transmissivity of plexiglass (up to 92%) is higher than that of glass (80 – 90%) so it looks clear even in thick sheets. For this reason, is often preferred for museum display applications. However, plexiglass can gradually turn yellow when exposed to UV (sunlight) light.

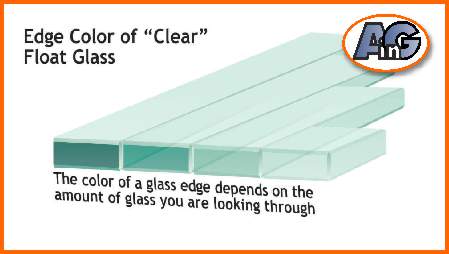

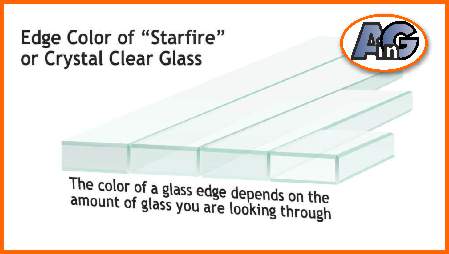

In contrast to plexiglass, regular clear float glass has a pale green tint owing to a small iron content. Special, low-iron glass is available at a premium price but still is not as “clear” as plexiglass.

Plexiglass is stronger than glass

Regular plexiglass is much more impact resistant than annealed glass and also stronger than tempered (heat-strengthened) glass. The impact resistance of tempered glass is about 10 joules compared to 12 for plexiglass – explaining why you see plexiglass barriers around ice hockey rinks.

But note that polycarbonate (Lexan) is even stronger (up 200 joules). Lexan will be the subject of a future blog post.

Plexiglass breaks into angular fragments as shown in the image above – unlike the popcorn fragments of broken tempered (safety) glass. Learn more about tempered glass in this post.

Plexiglass is softer than glass

Plexiglass scratches much more easily than glass. Tempered glass (used for windows etc) has a hardness of about 6 on Moh’s scale (diamond = 10). So it can be scratched by carbide steel or quartz (hardness 7). The hardness of plexiglass is often measured on the “pencil” scale and is scratched by hard pencil lead (4H) – this translates to about 3 on Moh’s scale so plexiglass is considerably softer than glass.

Polishing scratches in plexiglass is somewhat easier (using fine sandpaper and plastic polish) than polishing glass but this benefit is offset by the higher vulnerability of acrylic scratching.

Plexiglass is flammable

Plexiglass has a melting point of approximately 265–285°F (130–140°C ), which is very much lower than that of glass (approx. 1000°C or 1830°F).

Plexiglass catches on fire at 450° Celsius which classifies it as a highly flammable material.

This can create issues in interior design because most State building codes prohibit the use of inflammable materials for interior walls and ceilings. This means that desktop plexiglass screens are OK, but room-height dividers and cubicles are prohibited by code.

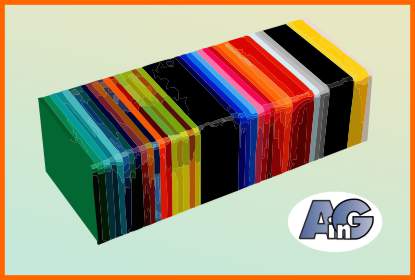

Plexiglass is available in various colors

Plexiglass is available in numerous both opaque and translucent colors whereas architectural glass (glass capable of being tempered) only comes in a limited range of tints. Other glass options include painted glass and so-called stained glass. Stained glass does come in an enormous range of colors but is only available in small sheets for use in leaded glass windows. Learn about the color in stained glass in this comprehensive post.

Environmental considerations

In this era of concern about climate change, the carbon footprint and sustainability of products have come under a detailed spotlight.

Mr. McGuire’s advice to Benjamin has turned out to be prophetic of the bête noire status of plastics in the modern ecological movement. Ignoring the obvious problems of plastic pollution in the oceans – what is the environmental footprint of plexiglass?

Acrylic (plexiglass)

The relative environmental impacts of plexiglass and glass are a complex matter to unravel and will be the subject of future posts. In brief, both glass and plexiglass are theoretically recyclable but, in practice, only 40% of glass is recycled and only 9% of plastics.

In terms of production, both products require energy but plexiglass production emits carbon dioxide, carbon monoxide, formaldehyde, and other compounds. This is very harmful to our environment. Acrylic is made out of petroleum and other toxic chemicals, a nonrenewable resource.

Artistry in Glass has gone to considerable steps to be ecologically responsible. and we conclude that glass is the lesser of two evils, as a cause of CO2 generation, when it comes to production. Since glass is endlessly recyclable, it is also preferable to plexiglass especially as more measures are taken to promote recycling.

Examples of applications plexiglass vs glass

Plexiglass vs glass for wall shelves

Whether you choose plexiglass or glass, it is always cheaper to purchase ready-made shelving systems rather than custom sizes. So, unless you have a special location that requires exactly sized shelves – it is sensible to save money on standard sizes.

Notice the benefit of simple plexiglass shelves below is that, unlike glass shelving, brackets are not required

The fact that plexiglass can be bent makes these shelves installable without metal brackets. Clear acrylic shelves from Amazon are 5mm thick, 12 inches long for bedroom, living room, or, bathroom – set of four

Standard sized glass shelves are also affordable but must be purchased together with supporting brackets – like this example below:

Available on Amazon these bathroom shelves are 24inches long & made of 5/16″ thick tempered glass with polished chrome brackets. More stylish and stronger than plexiglass but more expensive

In conclusion: choose plexiglass shelves if you are on a budget, but glass shelves for style and elegance.

Money-saving tip! Glass and mirror are essentially the same quality whichever shop you purchase them from. So save money by using these glass-buying tips from the experts at Artistry in Glass.

Useful price & weight calculators

1/8″ glass v 1/8″ plexiglass

1/4″ glass v 1/4″ plexiglass

3/8″ glass v 3/8″ plexiglass

Remember that the pricing modules above are just basic guides for custom sizes – big city costs will likely be higher and prices for standard-sized sheets may be lower.

Conclusion

Plexiglass is a strong, lightweight material that is clear and easy to machine. It can be used in place of glass for many applications, but it is more expensive and scratches more easily. It is important to consider the pros and cons of acrylic before making a decision about whether to use it in your next project. Call Artistry in Glass for detailed advice on the suitability of glass or plexiglass for your project.

Glass tabletops & shelves – info from Artistry in Glass

- Benefits of glass shelving – info from experts!

- How much do glass tabletops cost?

- Do glass shelves need to be tempered?

- What is the best thickness for glass shelves?

- Best edge type for glass shelves, polished or beveled?

- How much weight can a wall shelf carry?

- What color glass should my shelves be?

- Glass tabletops – 10 amazing benefits explained

- How to order a glass tabletop

- Best thickness for glass tabletops – expert advice

- Should glass tabletops be tempered?

- Should glass tabletops be beveled?

- How to paint a glass tabletop

- All about tempering glass tabletops!

- How to tell if your glass is tempered

- Can tempered glass be cut?

- How to protect your wood table with glass

- How to fix a scratched glass tabletop

- How to fix a chipped glass tabletop

- How to replace broken patio table glass

- How to measure for a glass tabletop

- Video – how to measure your tabletop

- Plexiglass vs glass – pros and cons

- Beveled glass table base – a case study

- Choosing between tempered & laminated glass

- Glossary of terms used in the glass business

All you need to know about art glass

Commissioning stained and etched glass

- Stained glass designs from Artistry in Glass

- How to commission a stained glass window – complete advice

- How to commission an etched glass window

- How to choose the best stained glass design

- Etched or stained glass – which is better for your home?

- How much does stained glass cost?

- How much does etched glass cost?

Technical information

- Is leaded glass dangerous? Learn the facts.

- How to replace broken patio table glass

- Plexiglass and glass – what are the pros and cons?

- What is plexiglass used for?

- What costs more – glass or plexiglass?

- Preservation of stained glass in churches & synagogues

- How does stained glass get colored? learn from an expert!

- Is your broken stained glass panel worth repairing?

- How to protect stained glass in religious buildings

- How to care for and clean stained glass

- How to repair cracked stained glass

- What is Dalle de Verre?

- How to repair Dalle de Verre

- What to do about bowed & sagging stained glass

- How to care for a stained glass skylight

- Can my stained glass lampshade be repaired?

- What is the difference between sandblasting & etching?

- Obscure and frosted glass – all you need to know!

- How to save money when buying glass

- Glossary of important terms used in decorative glass

- 14 Ways to sell stained glass

- What is imitation or faux stained glass?

Guides to stained glass design

- Guide for designing abstract stained glass

- Why choose abstract contemporary stained glass

- How to design a Frank Lloyd Wright-style window

- Designing a WWII-era stained glass Waco glider

- Stained glass and Black Lives Matter

- How Is stained glass used today?

Artistry in Glass was your source for antique repair in Tucson

Check out this amazing selection of informative articles:-

- Where can I get antiques repaired?

- Are broken antiques worth fixing?

- How to fix a broken picture frame

- How to repair a broken china plate

- How to repair a broken china teapot

- How to fix a broken marble slab

- How to repair a broken china coffee mug

- How to repair a 2000-year-old sculpture

- All about repairing stained-glass lampshades

- How to care for your stained glass skylight

- How to repair Dalle de Verre

- Is stained glass worth repairing?

- To repair or toss out?

- Tucson crystal & china repair a division of Artistry in Glass

- What to do with broken antiques

- Is lead crystal dangerous?

- Repairing an antique Mexican statue

- Repairing religious statues

- The history of Swarovski crystal figurines

- How to find the value of a Swarovski Crystal figurine

- Have Swarovski crystal figurines lost value since 2009?

- How to collect Swarovski annual ornaments

- How to display Swarovski crystal figurines

- How to authenticate a Swarovski crystal figurine

- How to display Swarovski annual ornaments

- How to clean Swarovski crystal figurines

- How to repair a Swarovski crystal mouse

- How to repair a Swarovski annual ornament

- How to repair a Swarovski crystal train set

- Fixing broken wine glass stems

- How to clean cloudy glasses

- Why do wine glasses have stems?

- Swarovski Crystal Figurines

- How to repair a chip in a wine glass

- How to fix a scratched glass tabletop

- How to replace a broken patio tabletop