Written by John Wakefield – Owner of Artistry in Glass

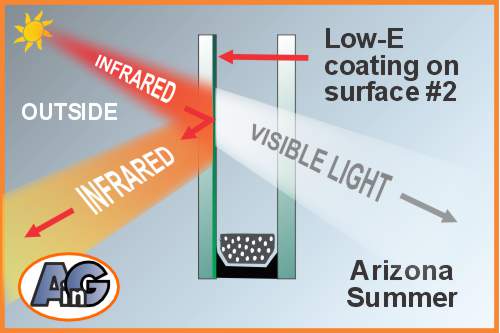

Low-E glass improves the energy efficiency of windows by enhancing insulation. During the winter, it reflects heat back into the interior, thereby reducing the demand for heating systems. In the summer, it reflects heat away from the building, decreasing the need for air conditioning. This results in substantial long-term energy savings, making Low-E Glass a widely adopted choice for both homeowners and businesses.

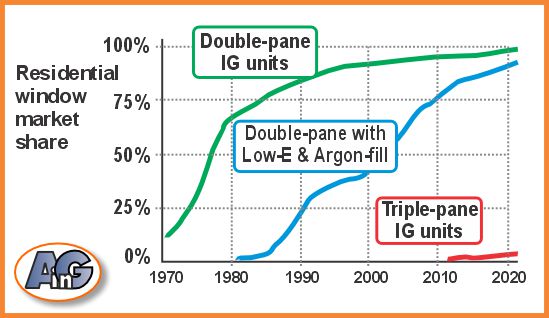

Low-E glass in argon-filled double-pane units is the best choice for replacement windows in nearly all US climatic zones and residential situations in 2023.

The technology is reliable, and high-quality windows will retain their Low-E coating for the lifetime of their windows (typically 20-25 years).

But what is Low-E glass, what types are available, and what are the benefits? Read all about Low-E glass in this comprehensive post.

What is Low-E Glass?

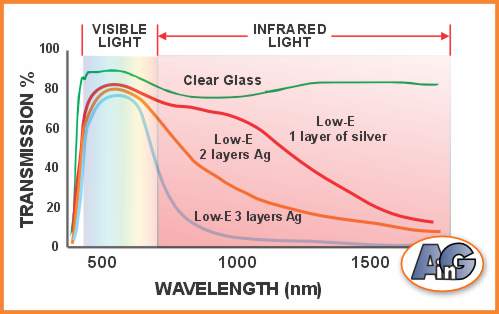

Low-E (low emissivity) glass has a microscopically thin layer of metal, such as silver or aluminum, applied to the surface using a vacuum deposition process. This layer allows light to shine through while reflecting UV and Infrared light to provide the desired level of heat reflection.

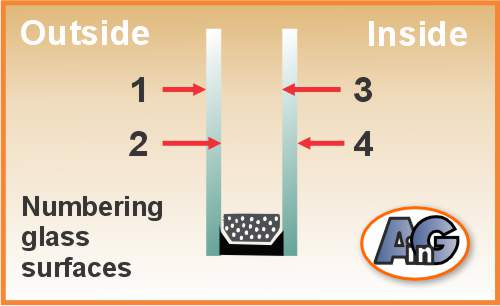

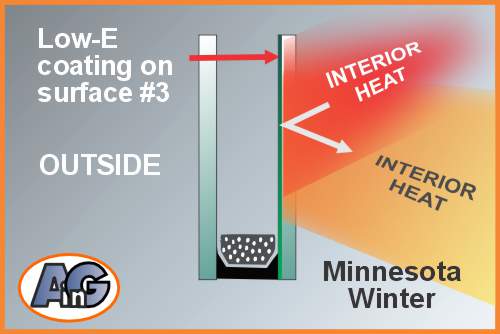

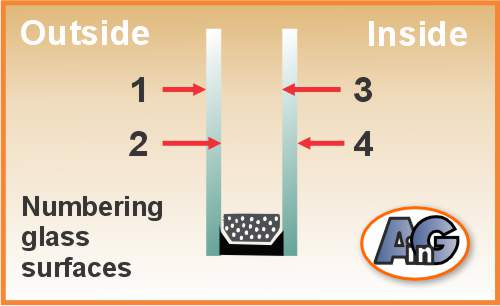

The Low-E coating is placed on surface #2 or surface #3 of a double-pane unit as explained below

Surfaces in a double-pane window

In the glass business, the surfaces on a double-pane window are numbered from one, on the outside, to to four on the inside:

In hot, southern climates like Arizona, the Low-E coating goes on surface #2 in order to reflect IR light from the sun. In cold climates like Minnesota, the Low-E coating goes on surface #3 where it can reflect interior heat back into the room.

In both cases, the delicate Low-E coating is protected from scratching or other damage.

We first explain the benefits of Low-E glass for the typical homeowner, then, if you are interested in science and technology jump to this section for the fascinating details.

Pros and Cons of Low-E Glass

The bottom line is that Low-E, double-pane glass with argon fill is the best replacement window solution for the average homeowner. The only reason to save money, by using regular glass, is for garage, shed, or utility room windows where heat and cold are not important.

The main pros and cons are:

Advantages of Low-E Glass

- Energy Efficiency – Infrared protection

- UV Protection

- Comfort Enhancement

- Noise reduction

Disadvantages of Low-E Glass

- Expense – Low-E glass costs more

- Reduction in visible light

As an Amazon Associate, I earn from qualifying purchases

Energy Efficiency

Low-E glass helps reduce energy consumption by reflecting the sun’s heat away from the building in the summer and retaining heat inside during the winter. This means that the building’s heating and cooling systems don’t have to work as hard to maintain a comfortable temperature, resulting in lower energy bills. In fact, windows with Low-E coatings can reduce energy costs by up to 25%.

Notice that, in hot climates, the coating goes on surface #2 whereas in cold climates it’s better on surface #3.

The combination of Low-E glass with argon fill is the key to maximum window efficiency. Argon cuts the Lowheat transferred by conduction and convection as explained in this post.

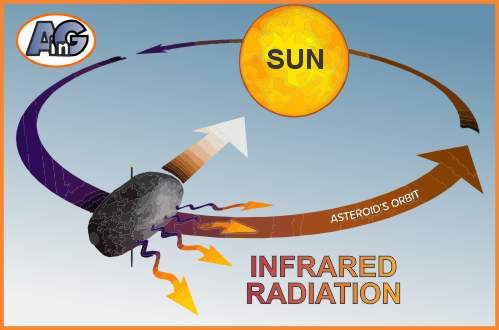

Fun factoid on Infrared radiation – it can alter the course of an asteroid!

Low-E coatings on Triple-pane windows

Triple-pane windows commonly have at least two low-E coatings. These produce exceptionally low SHGC values (0.16 in the example below) and very efficient windows.

UV Protection

Low-E coatings also block up to 99% of the harmful UV rays that cause fading and damage to furniture, flooring, fabrics, and artwork.

This protection is especially important for homes and buildings with large South- or West-facing windows or glass walls that receive direct sunlight.

Comfort Enhancement

Windows with Low-E glass improve the comfort level inside the building by reducing glare and minimizing temperature fluctuations. This can help create a more comfortable and productive environment for occupants.

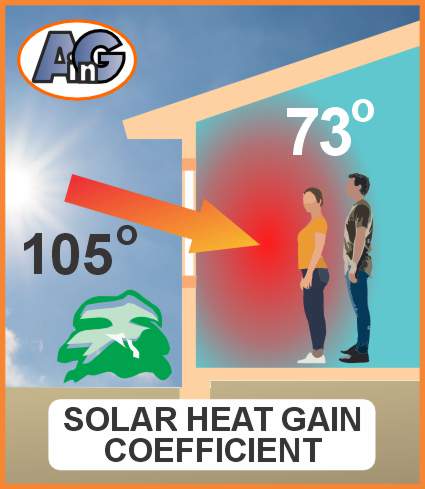

The Solar Heat Glass Coefficient is a measure of how much heat can pass through a window. See this post for full explanations.

Noise Reduction

Low-E glass reduces heat transfer and UV radiation, but it provides some level of noise reduction as a secondary benefit. The extent to which Low-E coatings help with noise reduction is not as significant as their impact on energy efficiency and UV protection.

The coatings themselves are relatively thin and do not have a substantial impact on sound insulation. However, Low-E windows are often built with multiple layers of glass and insulating gas between the panes, which contribute to better sound insulation compared to single-pane windows.

Disadvantages of Low-E windows

The bottom line is that Low-E glass is the best choice for most residential applications. The only downsides are:

Expense – Low-E glass costs more

Low-E coatings add approximately 7% to the cost of regular glass and the upcharge is well worth it for the reduction in Solar Heat Gain. Remember that you do not need this insulation benefit for sheds, garages, or utility rooms.

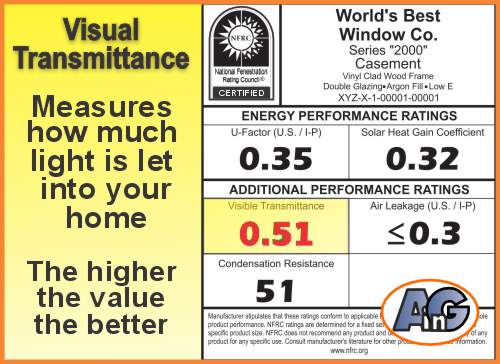

Reduction in Visual Light

One of the main limitations of Low-E coatings is that they can reduce the amount of visible light that enters a building. This can result in a darker interior space, which may not be desirable for some applications. Additionally, some Low-E coatings can have a slight tint or color, which can affect the appearance of the glass.

So there is a trade-off between Solar Heat Gain and Visual Transmittance.

Recommendation

Overall, Low-E glass in double pane units with argon fill offers a range of benefits that make them an excellent choice for energy-efficient windows. By reducing energy consumption, blocking harmful UV rays, improving comfort levels, and reducing noise pollution, Low-E glass helps create a more comfortable and sustainable environment for occupants.

Low-E insulated glass windows are available on Amazon. Thrifty homeowners can save money by installing their own windows. By doing it yourself the utility bill savings will be accelerated.

The Science of Low-E Coatings

To learn how Low-E coatings work, we need to understand the solar energy spectrum.

The Solar Energy Spectrum

The energy from the sun (solar energy spectrum) is divided into Ultraviolet (UV) light, visible light, and infrared (IR) light.

The differences between the three are determined by their wavelengths as shown in the animation below:

(Note that the spectrum above is for solar energy at sea level – the dips in IR radiation are caused by absorption by H2O and atmospheric gases.)

UV light

UV light has shorter wavelengths than visible light, making it invisible to the human eye. It is commonly classified into three categories: UVA, UVB, and UVC, with UVC being the most energetic and potentially harmful form. Although it only constitutes around 3% of the sun’s energy prolonged exposure to UV radiation can cause skin damage, including sunburn, premature aging, and an increased risk of skin cancer. Additionally, UV light can lead to eye problems such as cataracts.

In the context of windows, UV light is the main culprit for the fading and aging of fabrics, artwork, furniture, and flooring in the home.

Visible light

Visible light is the range of electromagnetic radiation that the human eye can detect and perceive. It consists of a spectrum (or rainbow) of colors, ranging from violet with the shortest wavelengths to red with the longest wavelengths, and it is what we need to illuminate and view the world around us.

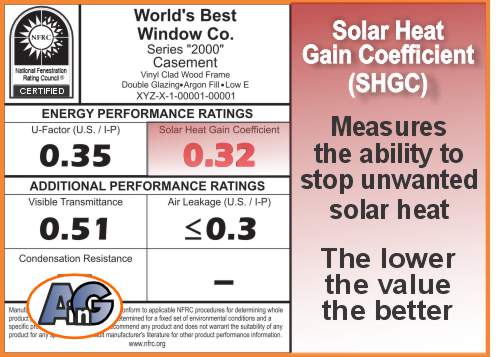

On Energy Star window labels, the clarity of the windows is called the “visual transmittance” and ranges from 0 (perfectly clear) to 1 (perfectly opaque/dark). Read more about labels in this post.

Infrared light

Infrared (IR) light is a form of electromagnetic radiation with longer wavelengths than visible light, making it invisible to the human eye. It’s commonly divided into three categories: near-infrared (NIR), mid-infrared (MIR), and far-infrared (FIR), each with distinct properties.

Infrared radiation carries heat energy (either from the sun or from heated objects inside your home). This heat energy can be absorbed by objects like the walls and furniture, contributing to the heating or cooling of your house.

In the window business, the measure of IR radiation is called the solar heat gain coefficient (SHGC) – this number appears on all window labels – see this post for how to understand labels.

The function of Low-E coatings

In terms of home comfort and energy efficiency, visible light is a good thing but too much UV is bad because it fades furniture and too much Infrared light is bad because it causes too much heat gain or loss.

Low-E coatings, or low-emissivity coatings are the amazing technological solution. Thin layers of metallic particles are applied to glass surfaces to reduce the amount of heat and light that passes through. These coatings work by reflecting some of the heat and light while allowing the remaining light to pass through the glass.

The trade-off between visibility and IR-blocking

Cutting out all damaging IR radiation would also cut down the visible light that is essential for lighting our homes. So there is a trade-off between stopping IR light and cutting visible light. The Energy Star labels on your window can help you understand the tradeoff. You want a low Solar Heat Gain Coefficient (<0.32) to cut heat and you want a high Visual Transmittance (> 0.51) to let in plenty of light.

Types of Low-E Coatings

There are two main types of Low-E coatings: Hard Coat and Soft Coat

Hard Coat Low-E

Hard coat Low-E coatings, also known as pyrolytic coatings, are applied to glass while it is still in the molten state. These coatings are made of a thin layer of tin oxide, and they are extremely durable and scratch-resistant. Hard coat Low-E coatings are commonly used in commercial and industrial applications due to their durability and ability to withstand harsh environmental conditions. They are also less expensive than soft coat Low-E coatings.

Soft Coat Low-E

Soft-coat, often called solar control, Low-E coatings are manufactured using the Magnetron Sputtering Vapor Deposition (MSVD) process, which means the coating is applied offline to pre-cut glass in a vacuum chamber at room temperature. This coating, which is also referred to as “soft coat,” needs to be sealed in an insulated glass (IG) or laminated unit. The soft coat has lower emissivity and superior solar control performance. This coating offers the highest-performing solar control.

Overall, both hard coat and soft coat Low-E coatings offer significant benefits in terms of energy efficiency and reducing heat loss. The choice between the two coatings depends on the specific application and budget constraints. Most residential double and triple-pane units have soft-coat low-E coatings on surface 2 and or 3.

Conclusion

Low-E glass is like magic for making your windows super energy-efficient. When it’s chilly outside, it bounces heat back into your room, and when it’s scorching hot, in the Tucson summer, they keep that heat outside. This means lower energy bills and comfier indoors.

Now, there’s a bunch of Low-E coatings out there, each with its own special powers. Some are like super reflectors, others are inconspicuous – you hardly notice they’re there. And some work better in the cold, while others shine in the heat.

But here’s the bottom line: all of them do the same trick. They reflect infrared radiation, keeping your precious heat inside where it belongs. This is a win-win, slashing your energy costs and giving your place a gold star for efficiency.

So, whether you’re trying to save some cash, make your home cozier, or just want to be a green superhero, Low-E Glass is the way to go.

FAQ

- What is emissivity?

- Are Low-E windows more expensive than regular windows?

- Can Low-E coatings be applied to different types of glass?

- Can Low-E windows be installed in any type of building?

- Do Low-E windows require special maintenance?

- Can Low-E windows be repaired if they are damaged?

- Do Low-E windows come in different colors?

- Do Low-E windows have an effect on plants?

- What is the lifespan of Low-E windows?

- Do Low-E windows need solar screens?

- Do Low-E windows fog up?

- Does Low-E coating go inside or outside?

- What is the difference between Low-E and tinted glass?

- Do Low-E Windows Affect WiFi or Other Radio Frequency Energy?

- What is the Yarkovsky Effect?

What is emissivity?

A surface’s emissivity means how much heat it gives off. Materials are rated on a scale from 0 to 1. A perfect reflector has an emissivity of 0 and a perfect absorber has an emissivity of 1.

Metals like silver and aluminum barely give off any heat, with scores less than 0.05. But regular clear glass is pretty bad at this, with a score of about 0.9. That means it lets 90% of the heat through and only reflects 10%. So, regular window glass isn’t great at keeping heat inside your home.

Are Low-E windows more expensive than regular windows?

Answer Yes. Low-E windows are typically more expensive than regular windows, but the energy savings they provide can offset the initial cost over time.

Can Low-E coatings be applied to different types of glass?

Answer Yes, Low-E coatings can be applied to different types of glass, including single-pane, double-pane, and triple-pane glass. In double- and triple-pane units the coating(s) are always placed on interior surfaces.

Can Low-E windows be installed in any type of building?

Answer Yes. Low-E windows can be installed in most types of buildings, including homes, offices, and commercial buildings.

Do Low-E windows require special maintenance?

Answer No. Low-E windows, or windows with low-emissivity coatings, generally do not require special maintenance compared to regular windows. In nearly all double and triple-pane windows the Low-E coating is on one of the inside surfaces – so cannot be scratched, stained, or otherwise damaged.

Routine maintenance for Low-E windows typically involves standard cleaning, such as wiping down the glass with a mild detergent and water, followed by gentle drying.

Can Low-E windows be repaired if they are damaged?

Answer No. The Low-E coating is rarely damaged because it is on one of the inside surfaces of a double- or triple-pane unit. If the coating is on an exterior surface and becomes damaged or compromised, it can’t be easily repaired or replaced on-site. In most cases, the best solution for damaged Low-E windows is to replace the entire window unit.

Do Low-E windows come in different colors?

Answer Yes. Low-E coatings are normally applied to regular clear glass. They are designed to maintain the natural clarity of glass while providing energy efficiency benefits. However, some manufacturers offer a limited selection of tinted options that can subtly alter the appearance of the glass, usually in shades like gray, bronze, pale green, or pale blue.

These options enhance aesthetics while preserving the Low-E coating’s energy-efficient properties.

Do Low-E windows have an effect on plants?

Answer Yes & No. Low-E windows have both positive and negative effects on plants. On the positive side, they protect indoor plants from excessive heat and harmful UV rays, helping to maintain a more consistent and comfortable environment. However, the reduced UV radiation may also limit the natural UV exposure that some plants require for optimal growth, particularly those that need direct sunlight.

To mitigate this, homeowners should position such plants strategically or use supplemental UV lighting. Overall, while Low-E windows can impact indoor plants, their benefits in terms of energy efficiency and comfort often outweigh any potential drawbacks for plant growth.

What is the lifespan of Low-E windows?

If the Low-E coating is on an inside surface (as normal) it will last indefinitely. In general, well-manufactured double-pane windows (with or without Low-E, can last anywhere from 20 to 30 years or more. Proper maintenance, such as regular cleaning and upkeep of seals and frames, can extend their lifespan. Additionally, the warranty provided by the manufacturer can give an indication of the expected longevity of the windows.

Do Low-E windows need solar screens?

Answer No – not necessarily. Solar screens are mesh-like materials that are installed on the exterior of windows to block a portion of the sun’s heat and glare from entering the home while still allowing natural light to pass through. When used in conjunction with Low-E windows, solar screens can further improve energy efficiency by reducing solar heat gain during hot weather.

However, the decision to use solar screens with Low-E windows depends on various factors, including climate, window orientation, and personal preferences. It’s essential to consider the specific needs of your home and consult with a professional to determine if adding solar screens is a good idea for your situation.

Do Low-E windows fog up?

Answer No. Properly installed and maintained Low-E windows should not fog up on the interior side under normal circumstances.

Fogging happens when the seal on a double-pane panel is broken and water vapor enters the unit. This is not related to the Low-E coating.

Does the Low-E coating go inside or outside?

In nearly all cases, the Low-E coating is positioned on one or more of the interior surfaces of a double- or triple-pane unit. This protects the sensitive coating from scratching or other damage.

In double-pane windows, the Low-E coating is on either surface 2 or surface 3.

What is the difference between Low-E and tinted glass?

It’s important not to confuse Low-E coatings with factory-tinted glass. Low-E glass may alter a window’s appearance, but the factory color or tint of the glass is entirely different. While Low-E is intended for energy performance, factory-tinted glass is more for aesthetics, glare reduction, and to meet the visual design intent of the building facade.

Do Low-E Windows Affect Wi-Fi or Other Radio Frequency Energy?

Answer Not Much. The impact on Wi-Fi or RF signals depends on several factors, including the specific type of Low-E coating, the thickness of the glass, and the frequency of the RF signal. Generally, modern Low-E coatings are engineered to minimize interference with wireless signals, and the impact is mostly modest.

In practice, the effect on Wi-Fi and RF signals in buildings with Low-E windows may be noticeable in areas with weaker wireless signals or if multiple layers of Low-E glass are used. However, it’s worth emphasizing that the impact is typically limited, and many homes and buildings with Low-E windows have functional Wi-Fi and RF communication without significant issues.

Can infrared radiation change the course of an asteroid?

What is the Yarkovsky Effect?

The Yarkovsky effect is a consequence of the fact that change in the temperature of an object warmed by radiation lags behind changes in the incoming radiation. That is, the surface of the object takes time to become warm when first illuminated, and takes time to cool down when illumination stops.

The heated side of the asteroid emits infrared ration that exerts a tiny thrust on the body. Although small, the thrust is sufficient to change the orbit of the asteroid over periods of millions of years. This change in orbit can either send the body hurtling in towards the sun (and close to a collision with Earth, or send it out towards the edge of the Solar System.

Learn all about energy-efficient windows in these posts:

- What is Low-E Glass & how can it reduce your utility bills?

- How do argon-filled windows save on energy bills?

- Are replacement windows worth the investment?

- Understanding the Labels on Your Double-Pane Glass Windows

- Is Upgrading to Triple-Pane Windows Cost-Effective?

- The Ultimate Window Frame Material Challenge – which is best?