Glass is an amazing substance with countless uses in residential and commercial buildings. However, it has one major drawback – it is brittle and breaks into razor-sharp shards that are very dangerous and even life-threatening. For this reason, several types of so-called “safety” glass have been engineered to lessen the risks of injuries.

So, what is safety glass & why is it important?

Safety glass is specially engineered to prevent serious injuries caused by razor-sharp shards of annealed glass. The two main types are tempered and laminated.

As an Amazon Associate, I earn from qualifying purchases

Artistry in Glass cannot be responsible for actions taken as a result of information on this website. Never take risks with the safety of your family. Always consult a professional if in doubt.

The danger of broken annealed glass

The broken edges of annealed (non-tempered) glass are among the sharpest in nature (literally sharper than a razor blade). Large, triangular shards act as deadly daggers that can slice through the flesh and arteries of victims unlucky or inebriated enough to fall into a window.

Glass injuries are most commonly caused by:

- Automobile accidents

- Broken window glass in buildings

- Broken glass tabletops and shelves

- Accidents in glass & mirror factories

- Stepping on broken glass bottles – street litter

- Flying glass from hurricane debris

Jump to this post for a full discussion of the serious nature of glass injuries.

The need for safety glass

Consumer protection measures, pioneered by advocates like Ralph Nader, drastically reduced the rate of broken glass accidents during the latter years of the 20th century. In particular, safety glass is now mandated in automobile windshields and in many categories of residential and commercial windows.

Safety glass standards are designed to reduce the risk of death and laceration in the event that you fall through a glass door or window. Accidents like these can easily happen if you slip in the shower or walk into a glass door and thousands of these occurrences prompted the development of safety glazing codes.

The details of the building codes related to glass are complicated – for a comprehensive review – follow this post from the Federal Register. and see this most detailed explanation from the International Code Council.

Summary of building safety codes for glass

The infographic below summarizes the most important locations where safety glass is mandated:

In summary, glass safety codes (ANSI Z97.1 and CPSC 16 CFR 1201) mandate that any glass window or door that is in a position that it could be walked or fallen into has to be tempered or laminated.

Special consideration is given to situations where slipping on wet surfaces (swimming pools & bathrooms) is likely.

Finally, extra codes specify precautions that need to be taken with glass in challenging engineering situations like sky decks, stairs, glass bridges, and glass railings, and also in zones vulnerable to hurricanes.

Jump to this section for details about glass on tall buildings.

Glass can be dangerous so always place the safety of your family first and consult an expert if you are in any doubt about glass choice or installation.

What are the main types of safety glass?

Architectural glass starts off as annealed float glass and is then processed to form the two main types of safety glass: tempered and laminated. Read on to learn about annealed glass:

Annealed glass

Most architectural glass is manufactured by melting silica sand, soda ash, dolomite, limestone, and sodium sulfate to 1480 degrees C, and then floating it on a pool of molten tin. (this is why it is called “float” rather than “plate” glass. The glass then passes through an annealing lehr – a furnace that controls the cooling process. The flat, solidified material at the end of the process is annealed glass.

This is cut into sheets and shipped to other factories where secondary processes, like polishing, drilling, notching, beveling, laminating, and tempering, take place.

Tempered glass

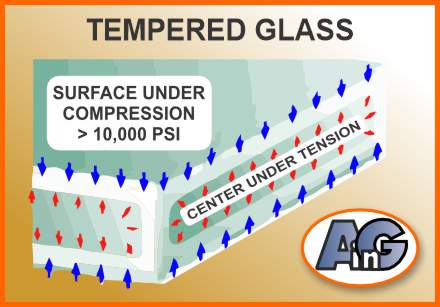

After the annealed glass is cut to size it is passed, on rollers, through a tempering oven which heats it to a temperature of 620 degrees C.

In the tempering oven, the hot glass is quickly “quenched” by high-pressure air from a series of nozzles. Quenching cools the outer surfaces of the glass much more quickly than the center, forming a hard skin.

The quenched glass is then cooled slowly and as the center of the glass gradually loses heat, it tries to pull back from the rigid outer surfaces. As a result, the center remains in tension, and the outer surfaces go into compression, giving tempered glass its strength.

The quenched surface makes tempered glass 4 to 5 times more impact-resistant than annealed glass – meaning that it is very hard to break, even when struck with a hammer.

What makes tempered glass safe?

When tempered glass breaks it forms thousands of small “popcorn” size fragments which are harmless. This is the characteristic that makes tempered glass safe to use in areas where the public is in close contact with windows, doors, and shower enclosures.

So tempered glass is considered to be safety glass because of the following two crucial properties – it is hard to break and it is not sharp when broken.

It is important to understand that tempered glass can still be dangerous to the public, especially when installed in tall buildings and in challenging engineering situations like sky decks.

Find out all about tempered glass in this comprehensive post.

Laminated glass

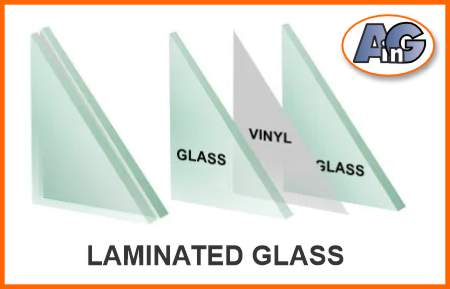

“Laminated” glass is made of two sheets of glass (they are generally annealed – but can be tempered) with an interlay of polyvinyl butyral (PVB).

When laminated glass breaks, the fragments stick to the PVB interlayer and do not fly or fall.

A vehicle windshield is made of a layer of laminate sandwiched between two layers of glass.

The laminate gives windshields strength to maintain a vehicle’s structural integrity during a crash. However, note that side windows are mostly not laminated and so can be the cause of glass-related injuries, especially in high-speed crashes.

Learn more about the benefits of laminated glass in this post.

Laminated glass for hurricane resistance

A crucial safety problem during the high windows generated by hurricanes and tornadoes is the failure of windows. When windows are breached the enormous pressure of hurricane-force winds enters the structure resulting in the removal of the roof and the destruction of the building.

Accordingly, in hurricane-prone areas, states like Florida and Texas have established strict building codes to protect buildings against high winds and flying projectiles.

Homes with laminated glass benefit, not only from hurricane protection by also from the elimination of UV fading, and reduction in noise pollution.

Choosing between tempered and laminated glass

Both tempered and laminated are classified as “safety glass” – so how do you choose between them? Study this post for everything you need to know.

To summarize; you should choose laminated glass to secure your home, to reduce UV light & sound pollution. Choose tempered glass for safety and strength in shower enclosures, patio doors, tabletops & shelves.

Notice, in the animation below, how laminated glass maintains its integrity and protects your valuables from burglars:

Is wired glass considered to be safety glass?

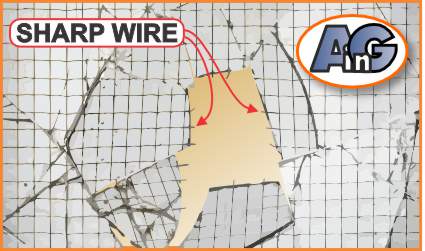

Wired glass is used as an approved fire-protection glazing for fire doors and windows installed in corridors, stairwells, gymnasium walls,

Its use is based on the mistaken belief that the wire will hold the glass together in the case of fire.

However, the consensus of expert opinion is that the embedded wires weaken the glass and substantially reduce its impact resistance, so wired glass is in fact only half as strong as ordinary annealed glass.

Wired glass is also more dangerous than regular glass when it breaks because the exposed wires are sharp and catch a victim’s hand or arm in the opening increasing the severity of the injury.

Children and young adults are seriously and permanently injured every year as a result of the dangerous use of wired glass vision panels in areas where impact-resistant glazing is required.

There is a long-standing dispute between the U.S, Consumer Product Safety Commission (CPSC) and the ANSI (American National Standards Institute) on whether the use of wired glass should be restricted.

Artistry-in-Glass recommends that any parents involved in school building planning should mobilize public opinion against the use of this dangerous glass.

Broken glass tabletops

Glass tabletops are a very common cause of series injuries – mainly due to victims falling into and through a glass not that has not been tempered.

Read this post in detail to learn about safety issues with tabletops and find out which tops must be tempered.

Take advantage of excellent prices and free shipping on this 48″ diameter tempered glass tabletop – available on Amazon with expert packaging for safe delivery.

Safety tips for workers in glass factories

The main risks for workers in glass factories are serious lacerations, and soft tissue puncture wounds resulting from contact with sharp and broken glass.

Commonsense strategies for reduced glass-handling injuries are shown in the infographic below:

In summary:

- Remove sharp edges by sanding (seaming) whenever possible.

- Never carry glass above your head.

- Work in pairs when carrying large panels.

- Carry glass by your side using two hands.

- Use sensible hand and body positioning to be out of range if the glass breaks.

- Do not try to hang on to breaking glass – jump out of harm’s way.

- Always wear gloves, arm guards, boots, and appropriate safety clothing.

- Always be aware of obstacles and the details of your surroundings.

Dangers of glass in tall buildings

Even though tempered glass is considered to be “safety glass” it can still be dangerous if a window fails and glass fragments fall from tall buildings.

Injuries to the public from curtainwall glass

With the evolution of the steel-supported skyscraper in the mid-20th century, glass windows have become ubiquitous. They protect buildings from the weather, keeping rain and wind out and moderating the temperature by providing insulation.

Curtain walls are very often made of glass in aluminum frames – they add stability to the building by dispersing wind stresses. They also slow the spread of fire between stories because glass and aluminum are not flammable.

When properly insulated and glazed curtainwalls improve the thermal efficiency of the buildings cutting down the operating costs, reducing UV light, and adding stability.

Building codes and conscientious contractors have made accidents with glass curtainwalls rare but when they occur they can be deadly as the following gif demonstrates.

Although curtainwall failure is very rare, glass sometimes breaks for no obvious reason. Causes for failure include glass edge defects or surface damage from handling that weakens the glass and makes it vulnerable to breakage due to high winds, asymmetrical heating, building movement (subsidence or earthquakes), vandalism, or inclusions in the glass.

Safety glass in balconies and skydecks

For highly critical engineering challenges made from glass, architects commonly specify combinations of tempered and laminated glass. Tempered glass provides the impact resistance and laminated glass, the security to hold the panels in place.

Similar types of glass projects have proliferated in China in recent years – several of these engineering marvels have failed during high winds.

Limitations of safety glass

Safety glass is designed to reduce the severity of cuts and lacerations but it cannot prevent you from falling through the glass. It is also not designed to prevent the broken glass from falling out and injuring people who might be below a broken window or balcony railing glass.

If glass is not adequately attached to its frame, broken chunks can be very dangerous for people below.

Street glass injuries

A very common source of business for inner-city emergency departments is cuts on the feet of kids playing in the streets without footwear.

Nickel sulfide inclusions and spontaneous glass failure

The most dangerous type of inclusion is a nickel sulfide stone, which occurs very rarely by contamination during the melting of ingredients for glass. Small amounts of nickel from stainless steel combine with sulfur to form inclusions of nickel sulfide (NiS). These microscopic stones become a problem during the tempering process when NiS is “frozen” in its high-temperature polymorph. With time, the stone can slowly revert to its low-temperature form that involves an increase in volume and the consequent mechanical stresses occasionally cause the failure of the tempered glass.

Strict safety protocols have been introduced to avoid contamination in the factories and the formation of nickel sulfide stones. It is also possible to re-annealed tempered glass to make “heat-strengthened” glass and revert the NiS to its low-temperature form.

In cases where glass failure would be disastrous (like glass platforms, stairs, bridges, and railings) engineers commonly combine laminated AND tempered glass to ensure safety.

Glass safety – learn from the experts!

- Choosing between tempered & laminated glass

- Broken glass injuries and how to avoid them

- Is wired glass safe?

- What is safety glass?

- What is tempered glass?

- What is Gorilla Glass?

- Plexiglass vs glass

- Should glass shelves be tempered?

- Should glass tabletops be tempered?

- Is lead crystal dangerous?

- Is leaded (stained) glass dangerous?

- How to repair cracked stained glass

Glass tabletops & shelves – info from Artistry in Glass

- Benefits of glass shelving – info from experts!

- How much do glass tabletops cost?

- Do glass shelves need to be tempered?

- What is the best thickness for glass shelves?

- Best edge type for glass shelves, polished or beveled?

- How much weight can a wall shelf carry?

- What color glass should my shelves be?

- Glass tabletops – 10 amazing benefits explained

- How to order a glass tabletop

- Best thickness for glass tabletops – expert advice

- Should glass tabletops be tempered?

- Should glass tabletops be beveled?

- How to paint a glass tabletop

- All about tempering glass tabletops!

- How to tell if your glass is tempered

- Can tempered glass be cut?

- How to protect your wood table with glass

- How to fix a scratched glass tabletop

- How to fix a chipped glass tabletop

- How to replace broken patio table glass

- How to measure for a glass tabletop

- Video – how to measure your tabletop

- Plexiglass vs glass – pros and cons

- Beveled glass table base – a case study

- Choosing between tempered & laminated glass

- Glossary of terms used in the glass business