Mirrors are used very widely in homes, businesses, and public buildings. You are accustomed to checking your appearance in a mirror, but how are mirrors made, and – why are copper-free mirrors the best choice?

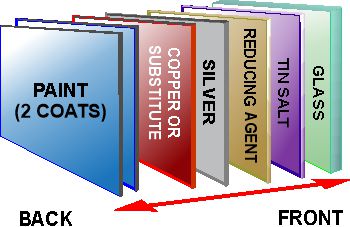

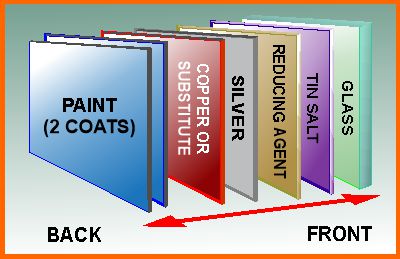

Mirrors are made by depositing metallic silver on the back of sheets of clear glass. The silver is protected by a copper-free coating and two layers of paint.

Most mirrors are made by the wet deposition method of coating metallic silver onto glass from a solution of silver nitrate. The silver was, for many years, protected by copper and then by coats of paint. New technology has removed the need for copper – resulting in environmentally friendly and corrosion-resistant copper-free mirrors.

Table of contents

What is the history of mirrors?

We are so used to seeing images of ourselves that it’s difficult to imagine a world without reflections. Using a mirror (looking glass) meant that, for the first time, people no longer depended on others to tell them how they looked. These days mirrors are just a part of modern living but industrially manufactured glass mirrors are a product of only the last few centuries.

The earliest mirrors

Our primitive ancestors no doubt noticed their reflections in bodies of still water, but the earliest fabricated mirrors were pieces of shiny or polished stone such as obsidian (a glassy black volcanic rock). Examples from modern-day Turkey have been dated to about 6000 BCE.

Polished copper was used for mirrors made in Mesopotamia and ancient Egypt in the period 4000 to 3000 BCE.

Copper and bronze mirrors

The use of metal mirrors spread throughout much of the ancient world in Europe and Asia and are found in such diverse locations as the graves of ancient Britons, the Russian steppes, and as far afield as, India, Sri Lanka, China, and Japan.

The first glass mirrors

The first glass mirrors were made by the Romans who coated the back of glass sheets with lead or gold leaf. Methods did not change until the early Renaissance when Venetian glassmakers perfected the technique of coating glass with an amalgam of tin and mercury enabling them to make large flat mirrors.

Antique mirrors from the Winterthur mansion in Delaware (photographed by John Wakefield). Both the Federal-style mirror (left) and the Rococo or Baroque-style (right) show the cloudy gray mottling characteristic of mercury mirrors.

The Venetian mercury method was capable of making moderately sized mirrors (up to about 40″ across) that were highly prized and very expensive. The mottled gray texture is duplicated to make reproduction antique mirrors.

For several centuries, Venetian glass makers guarded their monopoly of the tin amalgam technique. Venetian mirrors in ornate, often gilded, frames served as luxury decorations for palaces throughout Europe.

The Industrial Revolution and modern mirrors

In the late Industrial Revolution the ribbon machine allowed glass to be produced in large sheets and in bulk. This development made the production of large mirrors possible following the invention of the “wet deposition” method by German chemist Justus von Liebig in 1835.

The method of depositing a thin layer of metallic silver, by the reduction of a solution of silver nitrate, is essentially the same as that used today to make the vast majority of sheet mirrors.

As an Amazon Associate, I earn from qualifying purchases.

How many ways are there to make mirrors?

This article concentrates on the manufacture of silvered glass wall mirrors (the commonest type of mirror). There are numerous alternative shapes, styles, and types – for a brief summary: jump to this section of the web post

What is the “wet deposition” method for making mirrors?

The vast majority of sheet glass mirrors are made by the wet deposition method on industrial production lines in large factories.

The wet deposition method starts with polishing a sheet of clear glass. The glass is then “tinned” (treated with a tin salt solution). After rinsing, the silver layer is deposited by spraying a mixture of a reducing agent and silver nitrate solution.

The silver layer was formerly protected by a coat of metallic copper – but this step has been replaced by new, copper-free technology. Finally, two coats of protective paint are applied.

“Klopper” mirror conveyer courtesy of Contractors Wardrobe

Stages in the wet deposition method

The quality of a mirror depends first on the quality of the glass substrate. Most mirrors are made with so-called “clear” float glass that has a pale greenish tint owing to its iron content, but expensive low-iron (crystal clear) alternatives are available as well as gray, bronze, peach, and other tints.

Step 1: Cleaning and polishing the glass

Surface preparation: The first step in the production line uses rotating felt wheels with a slurry of cerium oxide to remove dirt & grease and produce a perfect polish ready for the silvering. Polishing actually removes a few microns from the glass sheet, exposing a virgin surface upon which the silver will be deposited.

Step 2: Rinsing with deionized water

Polishing is followed by rigorous rinsing to remove all foreign material. Water quality is an important consideration because impurities can lead to imperfection & tarnishing of the silver.

Powerful jets of deionized (DI) water clean the glass before the application of the “thinning” solution.

Step 3: “Tinning” the surface

Thorough rinsing of the surface is followed by “tinning” – a process in which the glass is sprayed with a solution of tin salts (stannous chloride). This solution prepares the surface to accept silver nitrate. Tinning is followed by rinsing again with DI water to remove any excess tin solution.

Step 4: Applying the silver

A mixture of silver nitrate solution and a special reducer is sprayed using separate nozzles aligned such that the sprays mix on top of the “tinned” glass. The reaction between the silver and reducer forms the reflective silver surface.

In small-scale operations, the mirroring solution is mixed and poured, rather than sprayed, onto the tinned surface as shown in the video below:

Step 5: Protecting the silver surface

Until recently, an important part of the silver protection was a layer of metallic copper that was applied, on the production line, by spraying diluted copper solutions and reducers through nozzles.

These solutions were not environmentally friendly because they contained lead as well as copper. Furthermore, the metallic layer was susceptible to corrosion under humid conditions – leading to damage like black-edge. (Learn all about damaged silvering in this post).

A major breakthrough, in the last 20 years, has been the invention of copper-free mirrors where the copper layer has been replaced by an environmentally friendly proprietary formula made by what are known as “GMP” (Good Manufacturing Practices). Follow this link to learn all about the benefits of copper-free mirrors.

Step 6: Applying protective paint

Two coats of tough protective paint are applied at the end of the production line to protect the silvering against corrosion and abrasion. The paint color has no real significance (it is used for identification). The paint is force-dried then the completed mirror is carried down the belt and flipped to the vertical to be inspected for quality control.

Step 7: Inspection and cutting

The completed mirrors leave the conveyor belt and are rotated into a vertical position for inspection. If they pass quality control they are cut into sheets ready for shipping to wholesalers and shops.

The importance of copper-free mirrors

A mirror’s environment is its worst enemy. Over time, humidity and other atmospheric conditions, cleaners with ammonium and many of the mastic adhesives used in installation eat away a mirror’s protective coatings and corrode its reflective surface.

The invention, in the last 20 years, of copper-free mirrors, has been a major breakthrough in mirror quality and durability. Humidity is not a major problem in most domestic locations but it is very significant in bathrooms and showers. So Artistry in Glass highly recommends that you specify copper-free mirror when employing a contractor for bathroom construction or remodeling.

Choose a certified copper-free mirror

Many modern mirrors are now copper-free but, to be sure, choose from one of these certified corrosion-resistant beveled mirrors available on Amazon. In the humidity of your bathroom, these mirrors will last longer before developing “black-edge”

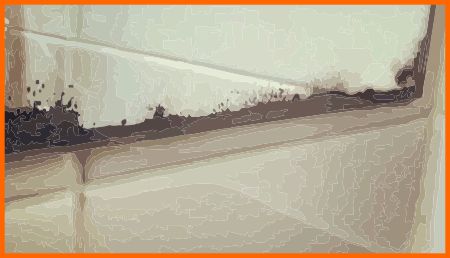

Mirror corrosion and the dreaded “black-edge”

Humidity in the bathroom has damaged the silver at the lower edge of this old mirror. Consider applying edge protection to your new mirror.

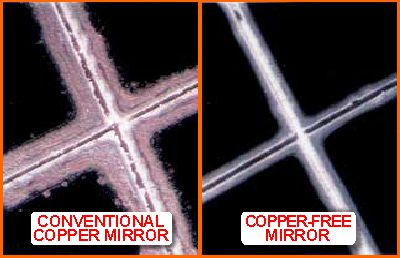

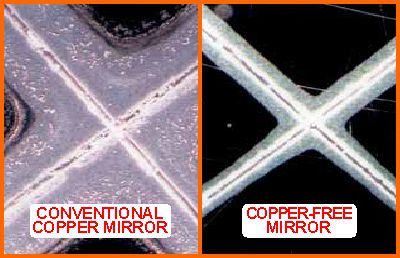

Laboratory testing proves the superiority of copper-free mirrors

Extensive testing has shown the superiority of copper-free mirrors:

Summary of corrosion test results (from Contractors Wardrobe Company)

Test results show that the copper-free mirror did not cloud after being in a humidity chamber for a period of 60 days whereas conventional copper mirrors showed clouding to various degrees after a period of fewer than 5 days.

The copper-free mirror showed NO clouding after 10 days of heat tests at 160° F. whereas conventional copper mirror was SEVERELY clouded after 4 hours.

The copper-free mirror showed NO paint delamination after being immersed in a 10 % ammonia solution for a period of 5 days whereas conventional copper mirrors delaminated after 3 hours.

Additional types of mirrors

Thick and thin mirrors

Most household wall mirrors are made from 1/4″ (6 mm) glass because it is a good compromise between strength and cost. Smaller mirrors are made from 3/16″ or 1/8″ glass to save weight and expense. See this useful guide for the prices of various types of mirrors.

Beveled mirrors

A bevel is the 1 inch wide angled edge that reduces the thickness of a 1/4″ thick mirror to 1/8″ and creates a sparkling decorative border effect for framed or unframed wall mirrors. Beveling can be done on 3/16″ or 1/4″ mirror but not normally on thinner (1/8″) mirrors.

Tempered (heat-strengthened) mirrors

Tempered mirrors are a good safety choice for large wall mirrors in commercial settings. They will greatly reduce your exposure and liability for injuries to your customers. Remember, however, that regular silvered glass mirrors cannot be tempered – the glass must be tempered before the silvering process. Learn about tempering here.

Colored or tinted glass mirrors

By using the wet deposition method on tinted glasses, various colors or tints of mirror are made. The most popular are bronze and gray – see this article for details about tinted glass. Simulated antique mercury or gold-veined mirrors are also manufactured by specialist mirror companies.

Planar and curved mirrors

Most wall mirrors are flat but non-planar mirrors have many applications:

Concave mirrors focus light and are used in reflecting telescopes.

Parabolic mirrors concentrate heat in solar generating systems.

Convex mirrors create diverging images useful as safety mirrors in hallways and driveways.

Irregularly curved mirrors are used as a source of fun in amusement arcades.

Front- and back-silvered mirrors

Most mirrors are “back-silvered” – meaning that the reflective layer is deposited on the back of the glass. This is the case with the vast majority of wall mirrors. Many telescope mirrors and also two-way mirrors have their silvering on the front surface. See the following images to determine the difference:

Aluminum and other mirror coatings

Modern mirrors use metals other than silver for special applications. The most important is aluminum which is deposited as thin films on the glass in a vacuum chamber using a process called sputtering. Aluminum is less reflective than silver over most of the visual spectrum but more reflective in the infrared and ultraviolet. It is also less susceptible to corrosion and slightly cheaper than silver. Most aluminum-backed mirrors available in the US are imported from China.

Metallic mirrors

As inheritors of the noble tradition of copper and bronze mirrors, modern metal mirrors, made from polished stainless steel, find their use today as a solution to vandalism in public restrooms.

Artistry in Glass is Southern Arizona’s expert for all things mirrored. Consult the extensive resources below or bring your mirror challenges into our Mid-town shop on East Fort Lowell Road.

Unique Mirror Resources from Artistry in Glass

Mirror Design & layout

- How are mirrors made?

- What is a beveled mirror?

- What is a two-way mirror?

- Best mirrors for bedrooms

- How to size and position your wall mirror

- How to order custom etched mirrors

- Best places to hang dining room mirrors

- How much do wall mirrors cost?

- Shop the MIRROR Family Package

Mirror Installation & Removal

- How to hang a wall mirror

- How to frame a builder’s grade bathroom mirror

- How to hang a frameless mirror with glue

- Best clips for hanging mirrors

- How to attach a mirror to a closet door

- How to remove a mirror glued to the wall

Mirror Repair & Restoration

- Should I resilver my antique mirror?

- Can I repair scratched mirror silvering?

- What is the best spray paint for mirror silvering?

- How to fix a cracked mirror

- How to repair a broken mirror frame

Artistry in Glass was your source for antique repair in Tucson

Check out this amazing selection of informative articles:-

- Where can I get antiques repaired?

- Are broken antiques worth fixing?

- How to fix a broken picture frame

- How to repair a broken china plate

- How to repair a broken china teapot

- How to fix a broken marble slab

- How to repair a broken china coffee mug

- How to repair a 2000-year-old sculpture

- All about repairing stained-glass lampshades

- How to care for your stained glass skylight

- How to repair Dalle de Verre

- Is stained glass worth repairing?

- To repair or toss out?

- Tucson crystal & china repair a division of Artistry in Glass

- What to do with broken antiques

- Is lead crystal dangerous?

- Repairing an antique Mexican statue

- Repairing religious statues

- The history of Swarovski crystal figurines

- How to find the value of a Swarovski Crystal figurine

- Have Swarovski crystal figurines lost value since 2009?

- How to collect Swarovski annual ornaments

- How to display Swarovski crystal figurines

- How to authenticate a Swarovski crystal figurine

- How to display Swarovski annual ornaments

- How to clean Swarovski crystal figurines

- How to repair a Swarovski crystal mouse

- How to repair a Swarovski annual ornament

- How to repair a Swarovski crystal train set

- Fixing broken wine glass stems

- How to clean cloudy glasses

- Why do wine glasses have stems?

- Swarovski Crystal Figurines

- How to repair a chip in a wine glass

- How to fix a scratched glass tabletop

- How to replace a broken patio tabletop