The terms Sandblasted and Etched are used interchangeably, by many craftsmen, to refer to frosted glass which allows light to pass through but diffuses it to provide privacy or to hide an unpleasant view. Strictly speaking, however, the processes are entirely different:

Sandblasting means removing glass with a high-pressure stream of abrasive grit whereas etching refers to the chemical reaction between glass and acid (typically hydrofluoric). These days, etching is used industrially for processing large sheets of frosted glass whereas sandblasting is used for most decorative purposes.

As an Amazon Associate I earn from qualifying purchases.

Sandblasted Glass

Sandblasted Glass is made by bombarding the glass with a pressurized stream of abrasive grit (originally silica sand but now, more often, aluminum oxide (because of the great danger of silicosis caused by inhaling Si02 dust)). When viewed under a microscope, the particles of grit are seen to have created numerous small craters as the hard particles of grit (Moh’s hardness 8-9) fracture the softer (5-6) but brittle glass. The larger the grit size and the higher the pressure – then the larger the micro-craters and the coarser the sandblasted surface. Typical grit sizes for decorative glass etching are 80# to 100# with air pressures of 30 – 50 PSI (pounds per sq. in).

The result of these numerous irregularities (micro-craters) in the glass surface is to diffract rays of light of various colors (wavelengths) in numerous overlapping directions with the result that the image is obscured and the light which emerges is (as Isaac Newton discovered in 1668) a combination of visible wavelengths – which interfere to produce white light.

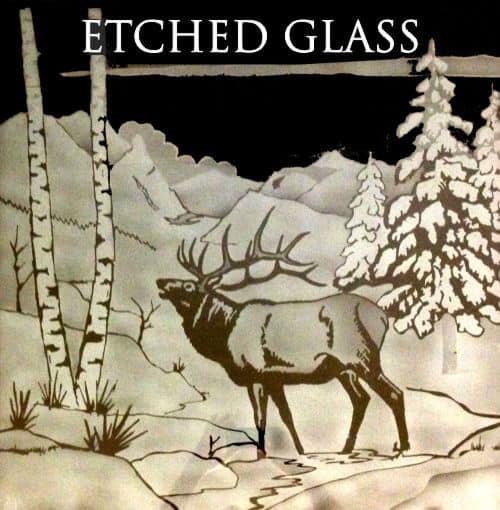

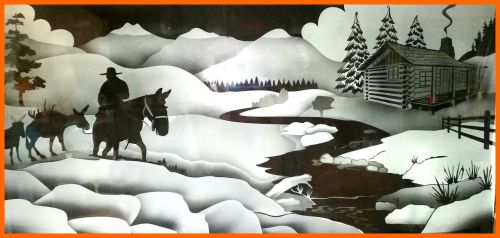

Sandblasting is used extensively to decorative glass and mirror panels producing works of art for residential and commercial applications. Techniques of sandblasting include simple frosting, shaded sandblasting), and deep carving, Most sandblasted art is uncolored and therefore, essentially a black and white artform (white being blasted and black being not blasted). Color-filling (painting) or gilding can be used in prestige projects.

Acid Etched Glass

The term “Etching” should, strictly speaking, be restricted to chemical or acid etching of glass. Acid-etched glass was extremely popular in Victorian times when elaborate panels were used to decorate mirrors and doors in hotels, pubs, and shops.

The etching acid is hydrofluoric (or a combination of HF and HN03) which is extremely toxic, corrosive, and dangerous. It is so potent that some unfortunates users in Medieval times were poisoned merely by its fumes. Accidents most often happened where acid dissolved into skin tissues resulting in mutilation or loss of the artisan’s fingers. In modern times acid etching is restricted to large, carefully controlled, industrial operations.

Armour Etch Glass Etching Cream 10oz Kit

For hobbyists, this excellent etching cream made by Armour is available on Amazon. We use it for small jobs like etching VIN numbers on car windshields. Amateurs like the ease of use for putting initials on drinking glasses but, for larger areas it is hard to get a consistent etch.

Etched glass is similar to sandblasted glass except that the imperfections which cause the frosted appearance are very much smaller. The result is a fine-grained “satin” etch which has the advantage over sandblasted glass that is is much easier to keep clean.

Acid-etched glass (without a design) is known under the trade name of “Mystique” or satin etch. It is perfect for both interior and exterior applications in houses, restaurants, hotels, and commercial buildings. Residential applications include furniture components, interior partitions, shelves, and, for privacy, in shower enclosures, doors, and windows.

Contact Artistry in Glass

Artistry in Glass has been sandblasting glass for commercial and residential and religious applications since 1986. Call John at 520-320-0104 for expert advice.

All you need to know about art glass

Commissioning stained and etched glass

- Stained glass designs from Artistry in Glass

- How to commission a stained glass window – complete advice

- How to commission an etched glass window

- How to choose the best stained glass design

- Etched or stained glass – which is better for your home?

- How much does stained glass cost?

- How much does etched glass cost?

Technical information

- Is leaded glass dangerous? Learn the facts.

- How to replace broken patio table glass

- Plexiglass and glass – what are the pros and cons?

- What is plexiglass used for?

- What costs more – glass or plexiglass?

- Preservation of stained glass in churches & synagogues

- How does stained glass get colored? learn from an expert!

- Is your broken stained glass panel worth repairing?

- How to protect stained glass in religious buildings

- How to care for and clean stained glass

- How to repair cracked stained glass

- What is Dalle de Verre?

- How to repair Dalle de Verre

- What to do about bowed & sagging stained glass

- How to care for a stained glass skylight

- Can my stained glass lampshade be repaired?

- What is the difference between sandblasting & etching?

- Obscure and frosted glass – all you need to know!

- How to save money when buying glass

- Glossary of important terms used in decorative glass

- 14 Ways to sell stained glass

- What is imitation or faux stained glass?