Most stained glass is put together in a framework of lead channel called came. Lead is a soft and pliable metal that deteriorates with age due to expansion & contraction, oxidation, and other reasons. When lead fails, the result will be bowed & sagging stained glass.

What should you do if you have bowed & sagging stained glass? Is this a serious problem? Should you call a professional? Find out in this post from the experts at Artistry in Glass.

Any stained glass panel that has bowed out more than 1 to 2 inches should be checked by a stained glass professional. It will need to be removed for repair (flattened, re-soldered, reinforced, and possibly re-leaded). If left unattended it will eventually fail catastrophically.

Table of contents

How is stained glass put together?

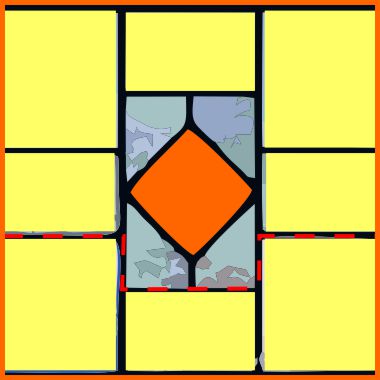

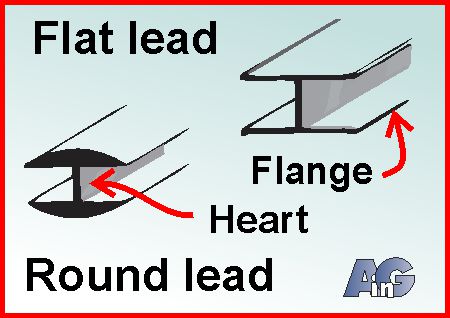

Note that, in this article, “stained glass” is used as an umbrella term to refer to any type of colored, textured, or beveled glass that is held together in metal came (an H-shaped channel most commonly made of lead, but also zinc and sometimes brass or copper) as shown in the animation below:

A note on lead poisoning – lead can be very dangerous – especially to children and pregnant women. Follow this link to learn more – before handling leaded glass.

The underlying reason for bowed & sagging stained glass

Stained glass is a very beautiful but also fragile form of artwork. Windows sag and bow for various reasons but the primary factor is that most old stained glass windows were designed to keep the weather out.

It is this vulnerable situation, exposed to constant variations of weather, heating, cooling, frost, rain, and snow that is the ultimate culprit.

Since the 1970s and 80s most stained glass is installed with exterior protective glass – so the delicate art glass is isolated from the weather and dangerous sagging is much less likely.

So, exposure to the weather: heating, cooling, rain, snow, hail, and worse is the primary, underlying reason for bowing and failure of stained glass panels.

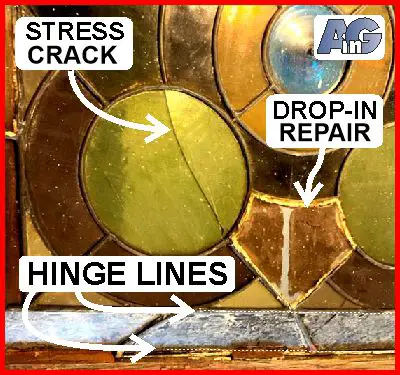

See the image below for the typical results of bowing and sagging on a vintage panel:

Multiple consequences of sagging stained glass in this 1920s-era panel. Damage includes stress cracks, detached pieces (repaired by the “drop-in” method), and buckling along parallel “hinge lines”

Before explaining the specific causes of bowed and sagging stained glass jump to this section for advice on protective maintenance:

Causes for bowed & sagging stained glass

The specific causes for bowed and sagging stained glass are:

- Metal (lead) failure due to expansion & contraction

- Metal (lead) oxidation due to chemical reactions

- Hinging due to unstable design (parallel horizontal lead lines)

- Support failure due to inadequate or failed reinforcing bars

- Frame failure: deterioration of the wooden, metal, or masonry frame

Lead failure

The ductility of lead means that it deforms easily by bending and stretching and so a leaded glass panel is continuously fighting against gravity. The irreversible process of “creep” results in sagging that is exacerbated by changes in temperature. Thermal expansion and contraction result in metal fatigue and failure of the lead, especially along the solder joints.

An ironic fact is that Medieval lead, used in the great Gothic cathedrals of Europe, has lasted much longer than the lead produced from 1850 to 1950. This is because Medieval lead was strengthened by the presence of traces amounts of impurities like antimony, arsenic, silver, and tin. Jump to this section to learn more about the historical composition of lead.

The second factor influencing the strength of the came is its shape and composition: In brief: zinc and brass came are much stronger than lead and there are also special lead cames with reinforced hearts for extra rigidity. Jump to this section for interesting details about came profiles.

Lead oxidation

Lead starts out silver in color and ages naturally to produce a protective dark bluish-gray patina. Experts protect lead against further oxidation by applying stained glass polish containing carnauba wax.

If unprotected and exposed to acid rain or other corrosive fluids serious oxidation (showing as white chalky coatings) can weaken both lead and zinc came.

Hinging (or accordianing) due to poor design

Parallel, horizontal lead lines that extend across the full width of a panel are very likely to act like hinges (or accordions) unless the panel is reinforced with rebar.

Continuous horizontal lead lines are always likely to cause bowing by hinging unless the panel is supported by steel rebar keyed into the frame.

A simple way to avoid hinging is to stagger the horizontal lead lines – producing a pattern that resembles brickwork. Notice that vertical lines can be continuous without causing a problem (in fact some craftsmen will use zinc on long verticals for extra strength).

Note that even with staggered lead lines, large windows still need to be reinforced to prevent sagging. Read on to lead about rebar.

Support failure due to inadequate or failed reinforcing bars

A rule of thumb for leaded stained glass is that any panel with a perimeter length of more than 14 feet needs to be strengthened by rebars. In detail, the need for reinforcing depends on numerous other factors including the nature of the metal framework – zinc, brass, or reinforced came is stronger than lead – and copper foiled stained glass is also stronger.

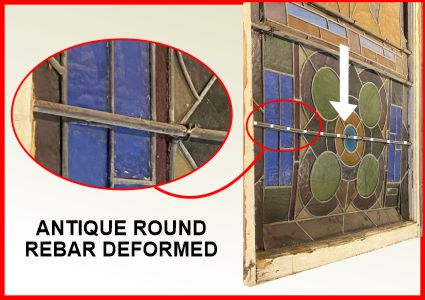

Antique round rebar is detached from wooden frame causing hinging along the lower, horizontal hinge line and consequent buckling.

Traditional round rebars (sometimes call saddle bars) are attached to the lead by soldered copper wires. Problems arise when the copper tie wires fail. Round rebar was gradually replaced with flat steel rebar (generally 1/8″ thick by 1/2″ wide) after the 1920s and 1930s.

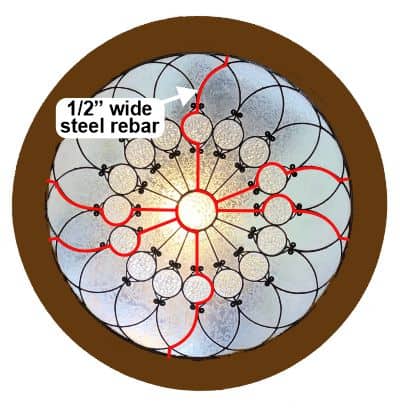

Rebar does not have to be straight – the red lines show the reinforcing bars, specially curved to follow the design of this Victorian-era skylight from the historic Blenman Inn in Tucson Arizona.

As an Amazon Associate, I earn from qualifying purchases

Frame failure – deterioration of wood, metal, or masonry

A stained glass panel is only as strong as the frame within which it is installed.

In residential windows, the typical frame from the 1870s through the 1950s was a wooden sash window. Unless carefully maintained, these are very vulnerable to weathering – wood and putty decay over time from moisture, UV light, and heat.

Steel frames also rust and corrode if not maintained properly and the glazing compound (putty) can come loose resulting in damage to the stained glass.

In public buildings and churches, the frames are often masonry that is long-lasting but can spall and flake owing to environmental attacks like acid rain.

In conclusion: custodians of stained glass panels must always pay attention to the condition of the frames because the rebars that prevent the window from sagging are not effective unless they are firmly attached to the frame.

The attractive panel (below) from a historic, 1940s home in Tucson, AZ looks fine from the inside. However, the exterior shows serious damage due to exposure to the hot Arizona weather. A vertical support bar is partly detached and the lower border has buckled out along the horizontal “hinge-line”. Furthermore, the wooden frame is severely dried out and weathered – it has been patched up with several generations of caulking.

The outside view shows the extreme effect of the hot Tucson sun causing drying out and weathering of the wood frame. A new vinyl or aluminum frame (with IG glass) is essential in addition to stained glass repair

What to do if you have bowed and sagging stained glass

- As a safety precaution, jump to this info on the dangers of lead poisoning before handling your leaded glass panel.

- Examine the damage carefully and take photos using your cell phone for insurance and repair purposes.

- Study the panels for signs of light holes (gaps in the glass)

- Carefully press the panels to check for rattling or movement

- Take close-up images of the buckled area and also an overall view so that the repair company can evaluate the method of installation and the difficulties that may be involved. Include a closeup of the molding – the pieces of wood or metal used to hold the panel in place.

- Stabilize the window by securing any loose or cracked glass with adhesive tape.

- If the panel is bowed out by more than 1-inch contact a local stained glass shop and email them images for advice. Tucson customers contact Artistry in Glass

This article shows how minor cracks can be repaired by a competent homeowner but, seriously buckled glass will require professional repair that will have to be done in the glass studio. Unfortunately, with glass removal and reinstallation, typical costs exceed $1000.00.

Learn more about the controversy surrounding the repair of bowed stained glass by following this link:

Care of stained glass

The most important preventative measure for damage to stained glass is to protect it against the weather. (study this video to learn about the care of religious stained glass)

Homeowners with unprotected stained glass should consider retrofitting their doors and sidelights with sheets of tempered glass (or even Lexan) to protect against expensive damage.

To prevent bowed and sagging stained glass use preventative maintenance by following the advice in this blog post.

If you notice cracks in your stained glass panel, the handy homeowner can make minor repairs by following the advice in this post.

UV-activated adhesive is specially formulated for glass repair. Seeps into cracks under capillary action and sets up in seconds under sunlight or a UV lamp.

After taking care of cracks, investigate for missing putty. If you notice dried putty (window glazing) coming loose, or if the panel rattles when gently pressed, a simple home repair is to add new putty:

We recommend this professionally stained glass putty available on Amazon. Squidge this black putty under the loose came using a small putty knife to stabilize your antique panel.

Leave the putty to dry overnight then carefully clean and polish:

We like this special glass polish from E.J. Wheaton. Apply and leave to dry to white then polish with a soft, microfiber cloth. The carnauba wax coat will protect your family against lead contamination.

Minor repair and maintenance can save big bucks in future series repairs!

History of lead came

Lead channel (called “came”) has been used since Medieval times to make stained glass. Ironically, lead made for the European Gothic cathedrals in the 12th, 13th and 14th-centuries was much stronger than 19th and early 20th-century lead because it contains traces of impurities.

The purity of lead

Around the 1860s, improved smelting methods enabled foundries to extract valuable metal impurities like tin, copper, silver, and antimony from lead, leaving the metal almost 100% pure.

The lead came manufacturers reasoned that 100% pure lead came would be superior but, as every metallurgist knows, alloys are stronger than the pure metal.

Unfortunately, the misconception that pure lead was better continued throughout the glory years of leaded glass use in America, and for this reason, several generations of windows were produced with weak and easily deformed lead.

Economies during WWII made lead of this era even weaker because the cames were made thinner to save lead for use in ammunition.

Due to its low melting point, lead is subject to “creep” at typical environmental temperatures. Creep means slow, permanent, deformation under constant stress, such as lead came supporting glass in a window. This means that the buckling and came cracking exhibited by many aging nineteenth- and twentieth-century windows is an inherent and unavoidable structural failure of the lead came resulting from the combination of modern refining processes and the nature of lead itself.

In the 1970s a new, improved lead formula was developed called “restoration lead” (ASTM B29-84). The composition was based on analyses of medieval cames, some of which have survived for centuries. Restoration lead should always be used when releading historic windows.

Profiles of lead and zinc came

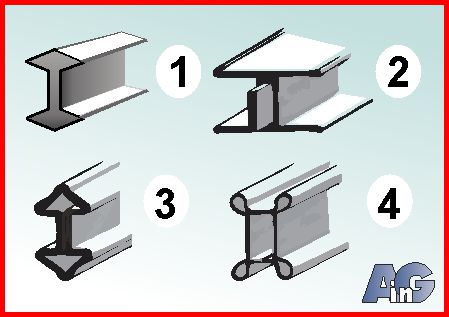

Experts can use the shapes of came for clues to the age of stained glass panels. Most lead came used for classic stained glass in churches and residences was made with weaker (pure) lead in the flat came morphology.

Most lead came from the classic period of American stained glass (1870-1930) was the flat lead variety – generally 3/16″ through 1/4″ and up to 3/8″ wide. Round profile lead has become the standard since the 1920s.

Distinctive profiles of lead and zinc came used throughout history. Medieval came (1) was poured into molds whereas colonial zinc (3) and Frank Lloyd Wright-style zinc cames were extruded in metal presses.

Repairing bowed stained glass – to re-lead or not!

There is a heated debate among stained glass craftsmen and experts over the best methods for restoring bowed & sagging stained glass.

The stakes are high because an entire generation of historic stained glass in churches and residences was built in the golden period from 1870 to 1920 and these windows are now more than 100 years old.

The majority view is to flatten the panel and restore it without re-leading.

The traditional method of repair is to remove the panel and lay it flat on the workbench under a flat board. With the addition of weights, with or without heat, the lead gradually (over a few days or a week) reverts to its original position by ductile creep.

The second stage is to carefully examine the flattened panel and carry out the required repairs that may include:

- Replacement of badly damaged lead came

- Re-soldering broken or defective solder joints

- Replacement or gluing of broken or missing pieces of glass

- Installation of modern reinforcing bars, soldered to the lead rather than attached by copper wires.

Finally, the restored panel is returned and reinstalled into (if necessary) the restored frame.

The contrarian view – complete re-leading

The case in favor of re-leading damaged panels is presented very persuasively in this excellent report. The authors carried out comprehensive tests (chemical, metallurgical, microscopic, SEM (scanning electron microscope analysis), and x-ray spectroscopy), and concluded that “…pressing a buckled window flat will not heal the cracks…and in fact, may cause new ones when the stretched metal is forced to lie flat again. This is a simple geometric response. The lead came walls cannot unstretch.”

They further determined that “soldering over visible cracks does not eliminate microscopic cracks.“

Finally, they conclude “…. that the service life of the lead-support system in a stained glass window is influenced by more than age. While the testing indicates that the older the lead is, the greater the likelihood of failure, chemical composition certainly influences its life span.

Traditionally, we may think that lead should be near 100 years old before considering replacement, but if it is relatively pure, that time span may be greatly shortened. Taking into account many other factors, including wind loads, climate ranges, installation types, and design style, the correct response to the signs of structurally failing lead is complete replacement with a new lead matrix.“

Implications for the repair of residential windows

At Artistry in Glass, we take a pragmatic approach to stained glass repair. There is no question that seriously deteriorated, historic church panels should be completely re-leaded with modern (strong) restoration lead but this very expensive procedure cannot be justified for more modest residential panels.

We have found that adequate and cost-effective restorations can be carried out without complete re-leading – and therefore recommend this process to our customers.

These days, sensible homeowners guard against breakage by installing protective tempered glass on the outside (and in some cases, also on the inside) of their art glass panels. However, many panels installed before the mid-1980s are stand-alone and unprotected.

Serious cracks and missing pieces really need the expertise of professionals like Artistry in Glass.

Study this video to see if your stained glass window is worth fixing:

The danger of lead

Lead in the form of came (channel) or in solder is an important part of a stained glass panel and lead is poisonous.

In summary: stained glass windows pose no threat to the homeowner providing simple precautions are taken. But, please read this post to learn all about the danger of lead in stained glass.

Lead is a dangerous poison, especially for young children and pregnant mothers! Take great care to wash your hands thoroughly after any contact with lead.

In conclusion

If you have a historic stained glass panel that is sagging or bowing always seek the advice of a professional. Leaving the panel unattended will eventually result in the glass falling out.

Save repair money by using a handyman to remove the panel and bring it yourself into our mid-town Tucson studio. If you are unable to remove the panel, call Tim or John at Artistry in Glass (520-320-0104).

Remember, never jeopardize the safety and security of your family by taking risks – be sure to contact Artistry in Glass at 520-320-0104 – if you are uncertain as to the best course of action.

All you need to know about art glass

Commissioning stained and etched glass

- Stained glass designs from Artistry in Glass

- How to commission a stained glass window – complete advice

- How to commission an etched glass window

- How to choose the best stained glass design

- Etched or stained glass – which is better for your home?

- How much does stained glass cost?

- How much does etched glass cost?

Technical information

- Is leaded glass dangerous? Learn the facts.

- How to replace broken patio table glass

- Plexiglass and glass – what are the pros and cons?

- What is plexiglass used for?

- What costs more – glass or plexiglass?

- Preservation of stained glass in churches & synagogues

- How does stained glass get colored? learn from an expert!

- Is your broken stained glass panel worth repairing?

- How to protect stained glass in religious buildings

- How to care for and clean stained glass

- How to repair cracked stained glass

- What is Dalle de Verre?

- How to repair Dalle de Verre

- What to do about bowed & sagging stained glass

- How to care for a stained glass skylight

- Can my stained glass lampshade be repaired?

- What is the difference between sandblasting & etching?

- Obscure and frosted glass – all you need to know!

- How to save money when buying glass

- Glossary of important terms used in decorative glass

- 14 Ways to sell stained glass

- What is imitation or faux stained glass?

Guides to stained glass design

- Guide for designing abstract stained glass

- Why choose abstract contemporary stained glass

- How to design a Frank Lloyd Wright-style window

- Designing a WWII-era stained glass Waco glider

- Stained glass and Black Lives Matter

- How Is stained glass used today?

Artistry in Glass was your source for antique repair in Tucson

Check out this amazing selection of informative articles:-

- Where can I get antiques repaired?

- Are broken antiques worth fixing?

- How to fix a broken picture frame

- How to repair a broken china plate

- How to repair a broken china teapot

- How to fix a broken marble slab

- How to repair a broken china coffee mug

- How to repair a 2000-year-old sculpture

- All about repairing stained-glass lampshades

- How to care for your stained glass skylight

- How to repair Dalle de Verre

- Is stained glass worth repairing?

- To repair or toss out?

- Tucson crystal & china repair a division of Artistry in Glass

- What to do with broken antiques

- Is lead crystal dangerous?

- Repairing an antique Mexican statue

- Repairing religious statues

- The history of Swarovski crystal figurines

- How to find the value of a Swarovski Crystal figurine

- Have Swarovski crystal figurines lost value since 2009?

- How to collect Swarovski annual ornaments

- How to display Swarovski crystal figurines

- How to authenticate a Swarovski crystal figurine

- How to display Swarovski annual ornaments

- How to clean Swarovski crystal figurines

- How to repair a Swarovski crystal mouse

- How to repair a Swarovski annual ornament

- How to repair a Swarovski crystal train set

- Fixing broken wine glass stems

- How to clean cloudy glasses

- Why do wine glasses have stems?

- Swarovski Crystal Figurines

- How to repair a chip in a wine glass

- How to fix a scratched glass tabletop

- How to replace a broken patio tabletop