Marble is a popular rock that has been used since Roman times for sculpture, building, and furniture. In the Victorian era, Carrara marble was commonly used for tabletops and unfortunately is often broken by careless moving companies. A cracked marble slab, with sentimental value, can easily be repaired by the handy homeowner:

- Check the edges to make sure they are clean

- Using a grinder, cut biscuit grooves to strengthen the join

- Apply 2-part epoxy adhesive to both sides

- Balance the 2 halves, so that the glue can set up under gravity

- Fill the missing areas with tinted epoxy

What is Marble?

Marble is a metamorphic rock resulting from the transformation of limestones under high pressures and temperatures. Typical marble is formed by interlocking coarse crystals of calcite (CaCO3) or dolomite (CaMg(CO3)2. The characteristic gray swirls are caused by mineral impurities such as iron oxide, clay, or silt.

Marble is a soft rock (Moh’s hardness is 3.5 to 4) and is easily scratched. It is also attacked by acids and so can be pitted and marred by common household products like vinegar. For these reasons, marble tabletops should be coated with a stain-resistant sealer.

Marble is also brittle and is easily broken due to careless handling (especially by moving companies). The breaks often follow a previous crack or a natural weakness like a vein or fissure in the rock.

Artistry in Glass is an Amazon Associate – we earn a commission from qualifying purchases.

How to fix a cracked marble slab

If you break a modern marble slab forming part of a kitchen countertop, consider replacing it with a new top. However, with antique marble having sentimental value and, especially with custom shapes, it is well worth attempting a restoration. For best results, follow these steps:

Examine the edges

To ensure a strong glue joint it’s essential that the two broken edges are perfectly clean, free from dirt and grease, and previous adhesives. If the crack occurs along a previous break it is highly likely that old adhesive will be present.

Different adhesives need different solvents for removal. In practice, a combination of dissolving and picking or cutting away the old glue with a chisel or Exacto knife is the best approach. Superglue (cyanoacrylates) dissolves in acetone and rubber cement needs a commercial paint stripper. Epoxies will loosen with heat but need a strong product like “Attack” Epoxy Adhesive Remover (available here on Amazon) for dissolving although “Goof Off” can sometimes be effective. In all cases, be sure to test an inconspicuous small area before proceeding, take care to read instructions, and follow safety precautions when using strong chemicals.

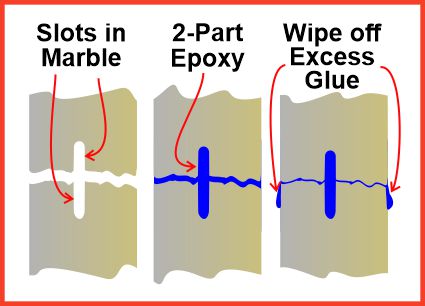

Optional “Biscuit” Jointing

Even with strong epoxy adhesive, considerable stress can be applied to the relatively small glued area of a 1″ thick marble slab, especially if the substrate is uneven. So, to make sure of a secure bond, Artistry in Glass has adapted the woodworkers’ biscuit joint technique to the gluing of marble slabs.

Because marble is soft it can easily be ground away using an angle grinder. Mark the two edges so that biscuit grooves correspond on opposite sides of the join. Be sure to wear goggles and a dust mask and also take great care not to chip the slab surface by cutting too close to the edges.

After cutting the biscuits, brush off all the dust and wipe down the surfaces with rubbing alcohol or acetone (these evaporate without residue), in preparation for gluing.

Balancing the Slab

Before applying the adhesive it’s very important to prepare a balancing situation because even using quick-setting (5-minute) epoxy, it is not possible to hold the two halves in place without arranging a support system.

It is almost impossible to line up a broken marble slab when it is laid flat. A counter-intuitive fact is that the best way is to support the two halves vertically.

If the break is clean, the two halves should “key in” together to form a perfect fit. Our recommended gluing method is to use the force of gravity to hold the upper piece in position while the glue hardens. We secure the lower part with woodworker’s clamps as shown above.

Gluing the Slab

There is an enormous and confusing range of epoxy adhesives available these days and it is hard to figure out which is best. The main factors that govern your choice for the repair of china, pottery, marble, and rocks are the setup speed, the color, the strength, and the possible degree of yellowing with exposure to UV light. Finally, the cost may be an issue if you are using a large amount. For a marble slab, strength is the most important characteristic and we recommend an epoxy like JB Weld “Clear Weld” which has an advertised shear strength of 3900 lbs/sq in.

Make sure the edges of the marble are perfectly clean and dry, then mix the epoxy, and apply generously to both sides. Normally, with a close-fitting join, for example on a china plate, we need a very thin layer of glue on just one side of the join – however, where we are using the biscuit joining technique we need to use sufficient glue to fill the biscuits.

Place the top piece in the position you have prepared and use tape if necessary to stabilize the join. Immediately wipe off any excess epoxy with alcohol – this will save considerable time scraping off dry glue later. Check the alignment and leave the pieces overnight to set up.

Filling the Crack

Even the cleanest break will have “micro chips” or small missing pieces that need to be filled. In our example, the break followed a previous fracture, a lot of material was missing, and a large amount of epoxy putty was needed.

Just as is the case with adhesives, there are numerous choices for epoxy putty: these will be discussed in a future post. For this type of repair, requiring a significant amount of material, we like the “Epoxie Sculpt” brand. Choose from natural color mixes to a neutral grey or white – both can be tinted by the addition of dry pigments or rock dust to match the marble.

Mix the 2-part epoxy putty thoroughly and tint it with pigment (if you can’t easily find artists’ dry pigments you can use powder scraped from chalks or artist’s pastels).

Spatulas (also called steel chisel sets) are very useful for squidging the putty into cracks. Using a spatula, force the putty into the crack and smooth the surface as level and even as possible. The smoother you get the putty, the less you will have to sand off when it is hard. Leave the epoxy putty to set up overnight.

Sanding & Painting the Repair

When the epoxy is dry it is time to complete the restoration. First, sand down the high spots until the putty is level (be careful not to scratch the unbroken marble). Go down through the grits from #200 to #1000 until the putty is perfectly smooth. (It may be necessary to fill micro-holes in the crack with a second batch of putty or filler).

Then, use your favorite paints (acrylics are OK) to finesse the color of the epoxy by adding off-white and gray swirls as necessary to match the marble. Have fun at this stage, feathering and shading the colors until the crack appears to disappear.

Varnishing the Marble

Even if you are successful in matching the colors, the crack will still be visible in bright light because of the difference in its reflectivity compared to the polished marble. The trick to completely disguise the crack is to apply a new sealing or varnishing treatment to give the surface a homogeneous appearance. You can apply a standard granite/marble sealer but a liquid of this type may react differently on the painted repair.

So, we recommend using a clear varnish from a spray can. These days, very high-quality aerosol varnishes, which are UV-resistant, and non-yellowing are available, in gloss, satin or matte finishes. (We like the high-quality Krylon, Colormaster brand), For most antique marble tops, a satin or semi-gloss varnish (like this available on Amazon) is normally the best.

Satin finish varnish will protect your antique marble

Satin finish varnish will protect your antique marble

Taking Care of Your Repaired Marble

An antique marble slab, repaired as outlined in this post should not be used as a work surface. It is safer to keep it as a decorative part of your furniture. To maintain your marble, just dust it with care: do not use any abrasive cleaners, Comet, or Scotch pads. If the surface becomes marred you can sand it delicately with fine steel wool and re-seal with a penetrating sealer or satin varnish.

Protecting your Marble Slab

If your antique marble will be used for cooking prep work, consider protecting it with a glass tabletop. Study this video guide from Artistry in Glass for all you need to know about protective glass tops.

Trust Artistry in Glass for your Tucson Repairs

Watch our informative video to see the range of restorations available at Artistry in Glass.

Unique Mirror Resources from Artistry in Glass

Mirror Design & layout

- How are mirrors made?

- What is a beveled mirror?

- What is a two-way mirror?

- Best mirrors for bedrooms

- How to size and position your wall mirror

- How to order custom etched mirrors

- Best places to hang dining room mirrors

- How much do wall mirrors cost?

- Shop the MIRROR Family Package

Mirror Installation & Removal

- How to hang a wall mirror

- How to frame a builder’s grade bathroom mirror

- How to hang a frameless mirror with glue

- Best clips for hanging mirrors

- How to attach a mirror to a closet door

- How to remove a mirror glued to the wall

Mirror Repair & Restoration

- Should I resilver my antique mirror?

- Can I repair scratched mirror silvering?

- What is the best spray paint for mirror silvering?

- How to fix a cracked mirror

- How to repair a broken mirror frame

Artistry in Glass was your source for antique repair in Tucson

Check out this amazing selection of informative articles:-

- Where can I get antiques repaired?

- Are broken antiques worth fixing?

- How to fix a broken picture frame

- How to repair a broken china plate

- How to repair a broken china teapot

- How to fix a broken marble slab

- How to repair a broken china coffee mug

- How to repair a 2000-year-old sculpture

- All about repairing stained-glass lampshades

- How to care for your stained glass skylight

- How to repair Dalle de Verre

- Is stained glass worth repairing?

- To repair or toss out?

- Tucson crystal & china repair a division of Artistry in Glass

- What to do with broken antiques

- Is lead crystal dangerous?

- Repairing an antique Mexican statue

- Repairing religious statues

- The history of Swarovski crystal figurines

- How to find the value of a Swarovski Crystal figurine

- Have Swarovski crystal figurines lost value since 2009?

- How to collect Swarovski annual ornaments

- How to display Swarovski crystal figurines

- How to authenticate a Swarovski crystal figurine

- How to display Swarovski annual ornaments

- How to clean Swarovski crystal figurines

- How to repair a Swarovski crystal mouse

- How to repair a Swarovski annual ornament

- How to repair a Swarovski crystal train set

- Fixing broken wine glass stems

- How to clean cloudy glasses

- Why do wine glasses have stems?

- Swarovski Crystal Figurines

- How to repair a chip in a wine glass

- How to fix a scratched glass tabletop

- How to replace a broken patio tabletop

Glass safety – learn from the experts!

- Choosing between tempered & laminated glass

- Broken glass injuries and how to avoid them

- Is wired glass safe?

- What is safety glass?

- What is tempered glass?

- What is Gorilla Glass?

- Plexiglass vs glass

- Should glass shelves be tempered?

- Should glass tabletops be tempered?

- Is lead crystal dangerous?

- Is leaded (stained) glass dangerous?

- How to repair cracked stained glass

As an Amazon Associate, I earn from qualifying purchases.