Tempered glass is used for shower and patio doors because it is strong and safe, But, once tempered, glass can’t be cut, polished, or drilled, So, if you want to cut your glass, how do tell if it is tempered? Discover the facts from a glass professional.

Very confusing websites give bad advice on how to identify tempered glass and even claim that tempered glass can be cut. We expose these ill-informed and confusing claims with definitive information from a 37-year glass professional.

To identify tempered glass look for a logo, view under polarized light, examine the corners & edgework, study score lines & look for surface imperfections.

What is tempered glass?

Tempered (sometimes known as heat-strengthened) glass is made by processing annealed glass in a special tempering furnace.

After the glass is cut to size it is passed, on rollers, through the tempering oven which heats it to a temperature of 620 degrees C.

Note that this diagram above is a repeating animated gif – the glass only goes through the tempering process once!

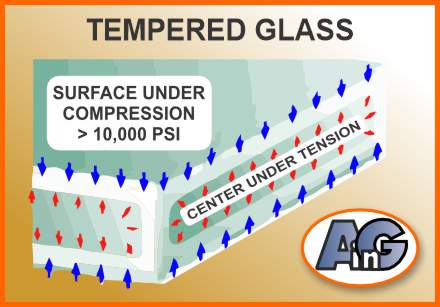

In the tempering oven, the hot glass is quickly “quenched” by high-pressure air from an array of nozzles. Quenching cools the outer surfaces of the glass much more quickly than the center. As the center of the glass cools, it tries to pull back from the rigid outer surfaces. As a result, the center remains in tension, and the outer surfaces go into compression, giving tempered glass its strength.

The result of this processing is that tempered glass is 4-5 times more impact-resistant than annealed glass and when it breaks it forms harmless “popcorn” fragments.

Tempered glass CANNOT be cut, drilled, or notched – it will explode into a thousand pieces!

As an Amazon Associate, I earn from qualifying purchases

How to identify tempered glass

If you want to cut your glass you must confirm that it is annealed. But as tempered and annealed glass look identical (same transparency, reflectivity, and refractive index) – how do you tell the difference?

Experts use 7 main methods to identify tempered glass:

- Look for an etched logo (bug)

- View under polarized light

- Examine a chipped corner

- Try the scratch or glass-cutter test

- Study the edgework (seamed or polished)

- Test the flexibility

- Look for surface imperfections

An etched logo proves the glass is tempered

Glass factories place an inconspicuous acid-etched or sandblasted logo (called a “bug” in the glass business) on one corner of a tempered panel,

Notice one crucial point: glass temperers will ask the retail glass shop whether they would like the logo (bug) or not. Some retailers leave off the logo because picky customers are offended by the appearance. So a piece of glass may still be tempered even if there is no logo.

In summary: an etched logo proves that glass is tempered but the absence of a logo does not prove that the glass is annealed.

View under polarized light

Hold the suspect panel up to the light and examine the glass through polarizing sunglasses. Tempered glass will show evidence for strain variations within the glass revealed by an optical property called birefringence.

You will see the same effect through your car windshield – this test proves that glass is tempered.

These polarized sunglasses from Amazon are probably the cheapest way to test your tempered glass – very reasonably priced.

Examine a chipped corner

If a corner of your suspect panel has been damaged, the shape of the chip will help you determine if the glass is annealed or tempered.

If you hit tempered glass on a corner it will very likely bust into thousands of pieces as shown in the video above. However, if the impact is less than that required for breakage, the chip that forms is a characteristic thin sliver that detaches part of the heat-strengthened skin of the glass.

In contrast, annealed glass forms a large V- or U-shaped chip where the strain is resolved as the fracture changes direction and heads for the nearest free edge.

The presence of a large (> 1 inch) chip proves that the glass is not tempered.

The glass cutter/scratch test

Although the properties of annealed and tempered glass are almost identical, the hardened surface of tempered glass is slightly more brittle. This means that, when scored with a glass cutter, tempered glass breaks into fine white flakes detached from the surface. The difference is subtle but very distinctive as the image below shows:

The cutter glides evenly over the annealed glass but scrapes and stutters over the more brittle tempered glass. (An experienced glazier can identify tempered glass from a subtle difference in the sound of the carbide wheel on the glass).

How to test

Scoring glass is a destructive process so do not try this test unless you wish to cut your pane of glass.

Prepare your glass using normal precautions (gloves and protective goggles), then score the glass in the desired location. Listen for the sound (smooth or scratchy) and examine the score closely. If necessary compare the score with one made on a scrap of genuine annealed glass.

Unbelievable value for a pencil-style oil-fed glass cutter with three heads (for three thicknesses of glass). Tested and recommended by Artistry in Glass. If you don’t want to buy a glass cutter a carbide scriber will work to test the glass.

If you suspect your glass is tempered you can try to break it (place a 1/4″ wood dowel under the score and press down). If it is tempered, the score will not run and if you press really hard the glass will break into popcorn pieces and you will have a glass cleanup to do!

Study the edges

Many misleading websites claim that the nature of the edge (smooth or rough) can indicate whether glass is tempered. The truth is more complicated as the image below shows:

The fact is that glass with any type of edgework – seamed (sanded), polished or beveled can be tempered or annealed. The edgework has no relation to the process of tempering except in the case of so-called “clean cut glass”.

The takeaway from this section is that glass with razor-sharp edges (clean cut) is definitely NOT tempered.

Jump to this section for examples of misleading info on the web.

Test the flexibility

If you have a long piece of glass that you suspect is tempered you can prove it by attempting to flex the glass. A long piece of 1/8″ tempered glass will bend remarkably without breaking.

Try this test with care – wear boots and protective clothing – just in case you are wrong and the glass is annealed rather than tempered.

Look for surface imperfections

Production methods and quality controls have improved markedly in recent years so imperfections are rare in tempered glass. In early tempering ovens, the glass was handled with tongs that left small indentations in the surface. In modern plants, the glass moves through the furnace on rollers so there are no tong marks but occasional fragments of glass may create surface imperfections.

Pretzeling or bending of tempered glass

There are industry standards for the amount of distortion permitted in tempered glass and modern factories produce extremely flat sheets. However, slight twisting (pretzelling) sometimes occurs in long narrow panels of thin (1/8″) glass because of edge effects. Look for twisting and distortion of reflections to prove that you have tempered glass.

Misleading information from misleading websites

There are thousands of honest and experienced tradesmen (and women) who know exactly how to identify tempered glass but do not know how to write a blog post. On the other hand, there are thousands of bloggers who know how to write but know nothing about tempered glass.

The ironic consequence is that a great volume of erroneous information is published on the internet by cynical bloggers with the aim of earning money from advertisements. Unfortunately, Google is so far unable to distinguish fact from fiction in many technical topics. Here are just two common errors, on the subject of tempered glass, perpetrated by ignorant bloggers:

Absence of logo

The lack of an etched logo (bug) in the corner of a pane of glass does NOT prove that the glass is annealed (ie not tempered).

This incorrect statement occurs on many websites. Many retailers order their tempered glass from the tempering plant specifying “no logo” (to please picky customers).

Smooth or rough edges

The nature of the edge has nothing to do with the tempering process. Edgework (seaming, sanding, polishing, beveling, etc.) is done BEFORE the glass is tempered.

The only hard and fast rule about edgework is that a pane of glass that is “clean-cut” (ie has razor-sharp edges) is definitely annealed (ie not tempered). This is because annealed glass has to have the sharp edges removed before processing in the tempering ovens. This is most often done by seaming (glass-lingo for sanding).

The moral: study the qualifications of the author

The key to finding reliable information is to study the qualifications of the author. Do not trust a home-improvement guru or an interior designer to give you technical facts about glass (they are probably just making it up!). Artistry in Glass has almost four decades of hard-earned experience in the glass business.

Shock glass pricing update

Effective July, 2022 the wholesale price of float glass & mirror has increased by between 20 and 40% According to the USGLASS News Network: “The combination of material cost increases, supply chain disruptions along with other economic pressures has forced companies throughout the globe to raise prices. These volatile factors have also impacted the glass industry, which has recently seen major companies such as Guardian Glass announce price increases and surcharges. Guardian is not alone, as five other industry companies issued price increases. These include Viracon, Vitro, Kuraray, Blue Star Architectural Glass and Oldcastle BuildingEnvelope®”.

To readers of the Artistry in Glass website – please note that glass & mirror prices quoted in various calculators should be multiplied by around 35% to obtain current retail pricing.

Glass safety – learn from the experts!

- Choosing between tempered & laminated glass

- Broken glass injuries and how to avoid them

- Is wired glass safe?

- What is safety glass?

- What is tempered glass?

- What is Gorilla Glass?

- Plexiglass vs glass

- Should glass shelves be tempered?

- Should glass tabletops be tempered?

- Is lead crystal dangerous?

- Is leaded (stained) glass dangerous?

- How to repair cracked stained glass

Glass tabletops & shelves – info from Artistry in Glass

- Benefits of glass shelving – info from experts!

- How much do glass tabletops cost?

- Do glass shelves need to be tempered?

- What is the best thickness for glass shelves?

- Best edge type for glass shelves, polished or beveled?

- How much weight can a wall shelf carry?

- What color glass should my shelves be?

- Glass tabletops – 10 amazing benefits explained

- How to order a glass tabletop

- Best thickness for glass tabletops – expert advice

- Should glass tabletops be tempered?

- Should glass tabletops be beveled?

- How to paint a glass tabletop

- All about tempering glass tabletops!

- How to tell if your glass is tempered

- Can tempered glass be cut?

- How to protect your wood table with glass

- How to fix a scratched glass tabletop

- How to fix a chipped glass tabletop

- How to replace broken patio table glass

- How to measure for a glass tabletop

- Video – how to measure your tabletop

- Plexiglass vs glass – pros and cons

- Beveled glass table base – a case study

- Choosing between tempered & laminated glass

- Glossary of terms used in the glass business